EVR-GSD4 Vacuum Regulator

| Port Sizes: |

|

||||

| Typical Pressure Ranges: |

|

||||

| Body Material (Standard): |

|

||||

| Body Material (Optional): |

|

||||

| Max CV: |

|

||||

| Key Applications: |

|

EVR-GSD4 Vacuum Regulator

The EVR-GSD4 is a small vacuum regulator with 1/2″ ports. This size EVR-GS vacuum regulator would be useful in vacuum table or vacuum holding applications where high precision and fast response are important.

EVR-GS Vacuum Regulator Series

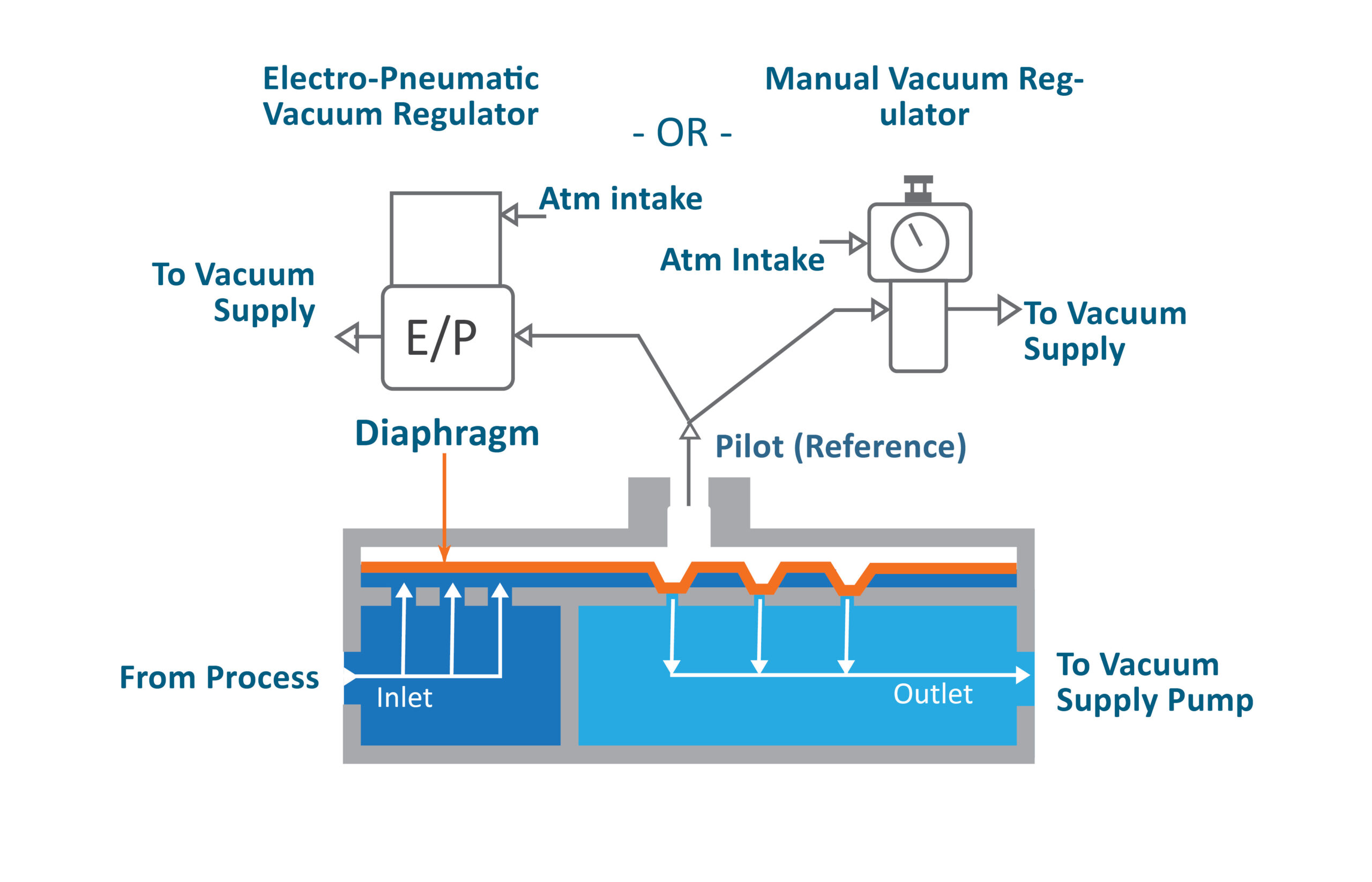

The Equilibar® vacuum regulator directly controls vacuum pressure by throttling flow between the vacuum supply pump and the process in order to precisely control the process vacuum to a specific setpoint. The EVR is a non-relieving regulator intended for processes where at least a very small gas flow is present at all times. Like our unique back pressure regulator technology, instead of a single large valve seat the Equilibar vacuum regulator uses multiple orifices sealed by a flexible diaphragm. The Equilibar is dome-loaded by a pilot regulator setting the vacuum setpoint. As flow requirements change, the diaphragm moves a few millimeters to open and close over some or all of the orifices, providing instantaneous and frictionless control. The pilot setpoint pressure may be set with a manual or electronic pilot regulator.

For more information contact one of our application engineers.

EVR-GSD4 Vacuum Regulator

EVR-GSD4 Vacuum Regulator

EVR-GSD4 Vacuum Regulator

Weight:

6 lbs (2.7 kg)

Dimensions:

Stainless Steel Models

Stainless Steel Models

DIM A – 4.5 in (114 mm)

DIM B – 1.6 in (41 mm)

Anodized Aluminum Models

DIM A – 4.5 in (114 mm)

DIM B – 1.6 in (41 mm)

PVC Models

DIM A – 4.75 in ( 121 mm)

DIM B – 1.8 in (46 mm)

Fitting/Threads:

Standard: NPT

Optional: BSPP; Swagelok VCO®; Swagelok VCR®; SAE; custom