Equilibar has several different trim styles and many different diaphragm materials in the Research Series designs to help meet many demanding research conditions. The Research Series back pressure regulators work through an incredibly wide range of flow, pressure, and temperature. Materials include Hastelloy, SS316L, PTFE, and FFKM (Kalrez), to name a few.

Maximum temperature ranges of the research back pressure regulators are standard 150°C, with the capability to go up to 200°C (with viton seals and metallic diaphragm) and 325°C (with Kalrez seals and metallic diaphragm). In extreme temperature cases, High Temperature (HT) models can be used in processes up to 450°C.

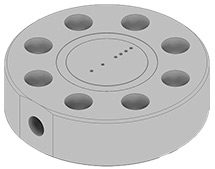

Primary Research Series Types

| Series Name | Internal image | Max Pressure psig/bar(g) | Min Cv | Max Cv | Advantages |

|---|---|---|---|---|---|

| LF Low Flow |  | To 1000 psig / 69 bar(g) | 1E-8 | 0.07 | Ultra wide flow range, superior multi-phase flow |

| HP High Pressure | To 10,000 psig / 690 bar(g) | ||||

| HF Higher Flow |  | To 1000 psig / 69 bar(g) | 1E-5 | 0.41 | |

| HPF High Pressure & Flow | To 10,000 psig / 690 bar(g) | 0.35 | |||

| HT High Temp |  | To 5000psig / 345 bar(g) | 1E-5 | 0.07 | High Temperature applications |

| HTF High Temp & Flow | To 5000 psig / 345 bar(g) | 0.35 | |||

| ZF Zero Flow |  | To 2000 psig / 140 bar(g) | Effective Zero | 0.01 | Nano flow range; excellent multi-phase flow |

| UL Ultra Low Flow |  | To 10,000 psig / 690 bar(g) | 1E-9 | 0.015 | Offers lower flow than HP in some applications |

Research Series valve are available in port sizes of 1/16″, 1/8″ and 1/4″ to accommodate most low flow / low dead volume requirements. For larger port sizes and flow rates see Equilibar’s General Service Series and Industrial Service Series valves.

Canadian Registration Number (CRN) certification available on select Research Series models for all territories and provinces. Please contact us for more information.

No matter if your application requires precision pressure control of liquid, gas, mixed phases, or even a slurry, our application engineers can specify a suitable back pressure regulator for your application.

Contact an Engineer Technical Literature

Use the table at left to view the family of research series products, then contact an application engineer to answer your questions.

Or use the product selector at the bottom of this page to choose a back pressure regulator by pressure or size requirements

Equilibar H3P high pressure research series back pressure regulator with an EPR 3000 high pressure electronic pilot regulator

Other Equilibar Back Pressure Products:

Research Series

Back Pressure Regulators

1/16" to 1/4"

up to 10,000 psig / 690 bar(g)

Research Series

Back Pressure Regulators

1/16" to 1/4"

up to 10,000 psig / 690 bar(g)

General Service

Back Pressure Regulators

1/4" to 1"

up to 2500 psig / 172 bar(g)

General Service

Back Pressure Regulators

1/4" to 1"

up to 2500 psig / 172 bar(g)

Industrial Service

Back Pressure Valves

1.5" to 4"

up to 150 psig / 10 bar(g)

Industrial Service

Back Pressure Valves

1.5" to 4"

up to 150 psig / 10 bar(g)

Electronic

Back Pressure Regulators

1/4" to 4"

up to 5000 psig / 344 bar(g)

Electronic

Back Pressure Regulators

1/4" to 4"

up to 5000 psig / 344 bar(g)