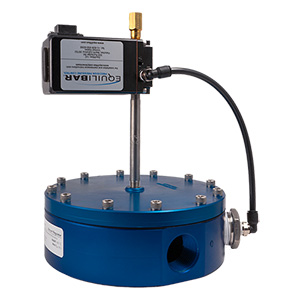

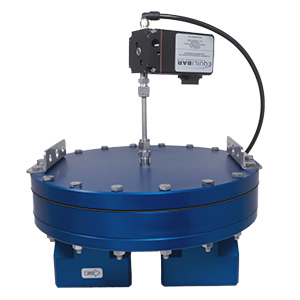

Electronic Vacuum Regulating Valves Sizes 1.5″ to 4″

Equilibar higher flow electronic vacuum regulating valves provide a much faster and more precise solution than traditional butterfly valves with PID control.

In the Equilibar® two-stage pilot operated solution, a small electronic vacuum pilot regulator sends a vacuum setpoint signal to the larger back pressure regulator (BRP), resulting in a controlled vacuum at the inlet of the BPR at a direct 1:1 relationship. An Equilibar high resolution electronic vacuum pilot regulator is used for this purpose. This combination of an electronic vacuum pilot regulator with a precision pilot operated back pressure regulator produces a complete electronic vacuum valve package. Electronic vacuum valves are available in traditional 4-20mA analog or in modern serial digital inputs.

These valves can be used in open loop mode or closed loop mode. In open loop, a command signal from the main computer controller is sent to the electronic vacuum pilot regulator. The vacuum pilot regulator transmits a vacuum setpoint signal to the Equilibar vacuum regulator which makes adjustments to bring the process vacuum very close to the pilot vacuum setpoint. Changes in flow rate may cause small errors in open loop mode.

In closed loop mode, the process vacuum pressure is monitored by a separate vacuum pressure sensor and command signal to the pilot regulator is adjusted to bring that process pressure to match desired setpoint. This PID action may be accomplished inside the electronic pressure regulator, depending on the model, or configured in the process control system.

Contact an application engineer to discuss the best way of automating your process vacuum.

Request a Quote Download Brochure

Electronic Vacuum Regulating Valve

Dimensional Drawing for EVR-BD Series

Metal High Flow Vacuum Valve Details

| Model | Inlet/Outlet Port | Reference Port | Standard Body Materials | Dim A | Dim B | Cv Range (precision) | Available End Fittings | ||

|---|---|---|---|---|---|---|---|---|---|

| Inch | Min | Max | Std | Available | |||||

| EVR-BD12 | 1.5″ | 1/8″ | SS316 (std) Anodized Aluminum | 9.5 | 3.9 | 1.0E-2 | 14.3 | NPT | BSPP; 150# Flange |

| EVR-BD16 | 2″ | 1/8″ | 11 | 4.1 | 3.0E-2 | 30.2 | |||

| EVR-BD24 | 3″ | ¼” | 15 | 6.1 | 6.0E-2 | 60 | |||

| EVR-BD32 | 4″ | ¼” | 20 | 8.1 | 1.5E-1 | 160 | |||

Polymer High Flow Vacuum Valve Details

| Model | Inlet / Outlet Port | Reference Port | Body Material | Diameter | Height* | Cv Range (Precision) | Available End Fittings | ||

|---|---|---|---|---|---|---|---|---|---|

| (inch) | Min | Max | Std | Available | |||||

| EVR-BD12 | 1.5″ | 1/8″ | PVC | 9.5 | 4.3 | 1E-2 | 14.3 | NPT | BSPP; 150# Flange |

| EVR-BD16 | 2″ | 11 | 5.1 | 3E-2 | 30.2 | ||||

| EVR-BD24 | 3″ | 1/4″ | 15 | 8.8 | 6E-2 | 60 | |||

| EVR-BD32 | 4″ | 20 | 9.6 | 1.5E-1 | 160 | ||||

| *Height is measured from top surface of regulator to the center of pipe elbow. Does not include 3″ manual set point regulator. | |||||||||

Other Equilibar Vacuum Control Products:

High Precision Vacuum Regulators

1/4" to 1"

0 - 30 inHg / 762 mm Hg

High Precision Vacuum Regulators

1/4" to 1"

0 - 30 inHg / 762 mm Hg

High Flow Vacuum Valves

1.5" to 4"

0 - 30 inHg / 762 mm Hg

High Flow Vacuum Valves

1.5" to 4"

0 - 30 inHg / 762 mm Hg

Electronic

Vacuum Regulators

1/4" to 1"

0 - 30 in Hg / 762 mm Hg

Electronic

Vacuum Regulators

1/4" to 1"

0 - 30 in Hg / 762 mm Hg

Larger Electronic

Vacuum Valves

1.5" to 4"

0 - 30 in Hg / 762 mm Hg

Larger Electronic

Vacuum Valves

1.5" to 4"

0 - 30 in Hg / 762 mm Hg

Vacuum

Pilot Regulators

mechanical, electronic

and remote sensing

Vacuum

Pilot Regulators

mechanical, electronic

and remote sensing