How Do Our Back Pressure Regulators Work?

The Equilibar® dome-loaded, multiple orifice technology works in a completely different way than traditional back pressure regulators and valves. Its synergistic design elements offer virtually instantaneous control and unprecedented precision for even the most challenging process conditions.

A supple diaphragm is the Equilibar’s only moving part, enabling frictionless operation without hysteresis or cracking pressure. Because it is dome-loaded, the Equilibar provides reliably stable pressure control. At the same time, the Equilibar’s multiple orifice design results in an ultra-wide flow range, typically 100 times industry norms. Its novel approach is often a good choice for the researcher or engineer who has already tried conventional pressure control products for difficult process conditions.

Read on for a more detailed explanation of this patented technology. And for information about the pressure reducing regulators, electronic regulators and other traditional and complementary offerings from Equilibar, see our full line of pressure control products.

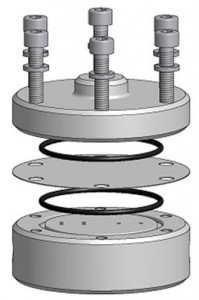

Equilibar Construction:

Inside the Equilibar, a diaphragm, sealed by O-rings, is sandwiched between the main body and the reference cap. The main body has parallel orifices that are covered and sealed by the diaphragm when not engaged. Every part of the Equilibar–the diaphragm, O-rings and the body itself–can be made from a variety of materials to meet the needs of a particular application.

Dome Loaded: The Equilibar is a dome-loaded pressure regulator with pilot operation. This means that gas or air is fed into the top (dome) area of the regulator to provide the pressure setpoint for the process. The pressure of the gas in the dome is set by a secondary standard regulator called a pilot regulator. The pilot regulator can be manual or electronic, depending on the application’s requirements.

The Magic Combination: Diaphragm and Multiple Orifices

A lightweight, supple diaphragm covers and seals the parallel orifices in the Equilibar body. As fluids flow through the unit, the Equilibar holds the process pressure to equal the pilot set point. The diaphragm lifts off the orifices to release pressure as the upstream process pressure exceeds the set-point pressure. When the flow is minimal, only a portion of one orifice will engage to release the pressure. When the flow is high, the diaphragm is pushed up to engage all the orifices. This flexibility accounts for the Equilibar’s exceptionally wide flow range.

The Equilibar can be compared to a fluid transistor that works by forming a unique force balance on the flexible diaphragm between three separate pressures—the pilot set-point pressure, the fluid inlet pressure and the downstream vent pressure. The fluid inlet pressure and the downstream vent pressure exist on the wetted side of the diaphragm, separated by the orifices. The pilot set-point pressure is on the non-wetted side of the diaphragm.

The Equilibar Difference:

Traditional back pressure regulators use springs to gradually open as the overpressure is used to compress the spring. This change in the spring constant as the spring is compressed is a major source of error.

The Equilibar design eliminates this problem and provides virtually instantaneous control.

During operation, the lower pressure at the Equilibar’s outlet tries to hold the diaphragm in a leak-tight seal with the orifice; however, even the slightest excess between the fluid inlet pressure and the pilot set-point pressure quickly overwhelms these seating forces and lifts the diaphragm off the orifices. The result is a lightning-fast response, keeping the inlet pressure in tight equilibrium with the setpoint pressure.

The novel combination of design elements gives the Equilibar the following advantages:

- Unsurpassed precision

- Exceptionally wide flow range capability

- Instantaneous response

- Frictionless control

- Compatibility with severe temperatures and chemistries

- Ability to handle two-phase flow of liquids and gases together

The Equilibar back pressure regulator provides unmatched stability through flow rate ranges as wide as 1000:1 and 10,000:1.