| Part # | Port Size | Pilot Port | Max. Operating Pressure |

|---|---|---|---|

| HV16 | 2″ | 1/4″ NPT | 10 inWC |

| HV32 | 4″ | 1/4″ NPT | 10 inWC |

| HV48 | 6″ | 1/4″ NPT | 10 inWC |

HV Low Pressure Control Valve Advantages:

- Automatically responds to changes in system flow rate

- Controls pressures near atmosphere accurately

- Able to handle corrosive media and aggressive vapors

- Able to control at high temperatures 150ºC/300ºF

- Easily and inexpensively field maintained

End Connections

- Weld Tube Stub

- Pipe Flange – ANSI 150# Class Typical

Body Materials:

- SS304 standard

- SS316L optionally

Diaphragm Materials:

- Viton (FKM)

- Buna-N

- PTFE

- Polyethylene

- EPDM

Gasket Materials:

- EPDM (std)

- Silicone

Request a QuoteDownload Brochure

Originally designed for ventilation applications, the HV Series can provide precision into the millibar range (down to around 1 inH2O / 25.4 mmH2 or 0.03 psig / 2 mbar(g)). The HV valve is able to control accurately at these low pressures because of its unique direct diaphragm sealing design. A thin flexible membrane is the only moving part. This diaphragm is used to directly seal against a field of orifices. There are no internal springs or sliding seals to create internal friction. The diaphragm has a large area which allows it to be sensitive to small changes in system pressure or flow rate. The unique sensitivity of Equilibar’s supple diaphragms give significant advantages over slow-reacting butterfly valves and other control mechanisms. The HV operates quickly and is able to automatically adjust to changes in as little as 10mS.

Like other Equilibar back pressure regulators, the dome-loaded design matches the inlet pressure to the pilot or setpoint pressure applied to the 1/4″ dome port. The unit can be used in either back pressure control, direct vacuum regulating, or in both modes. The unit will match the setpoint pressure provided to the reference port, be it a positive pressure or negative pressure. The HV series can control vacuum through positive pressures in gauge referenced or absolute referenced models.

The HV back pressure valve utilizes welded stainless steel plate metal construction to avoid the higher weight and costs of bar stock or cast body construction. Contact an Equilibar application engineer to configure the best solution for your high flow application.

Request a Quote

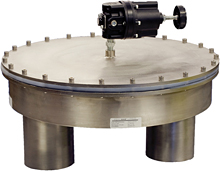

The HV32 back pressure control valve with 150# ANSI flanges.

Equilibar HV32 low pressure regulator with 4″ weld (butt) stub connections.

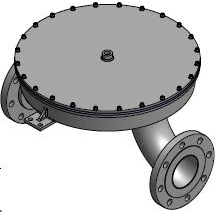

Isometric view of HV32 with 4″ ANSI pipe flange option

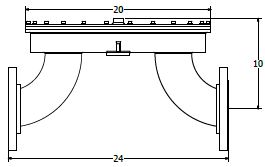

Dimensions for HV32 with ANSI 150# class pipe flange

The HV Series Back Pressure Control Valve controls pressure directly by matching the inlet pressure to the pilot pressure level.