We keep safety in mind as we collaborate with our customers to design precision fluid control systems specific to their process. Because Equilibar® back pressure regulators are uniquely qualified to perform well in challenging process conditions such as high temperature and corrosive environments, we take that into account in our designs and include precautionary information for our customers.

Equilibar back pressure regulators (BPRs) and vacuum regulators (EVRs) are dome loaded and require a second pilot pressure regulator to provide a setpoint pressure on the dome. While our BPRs and EVRs are designed to handle severe conditions, the pilot regulators are not. We recommend that our customers design safety measures into their process to prevent process fluids from harming the pilot regulators.

Below are some safety design suggestions we recommend. These are design suggestions only, intended to spark ideas and generate awareness of the risks. Suitability of any safety precautions are the responsibility of the user.

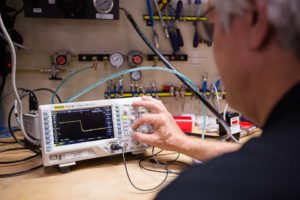

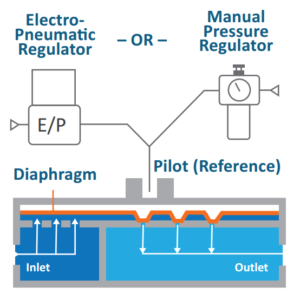

Equilibar BPRs and EVRs are controlled by a pilot regulator, either manual or electronic.

Equilibar BPRs and EVRs are controlled by a pilot regulator, either manual or electronic.

Back Pressure Regulator Safety Design Considerations

The diaphragm in our BPR separates the dome pressure fluid from the process fluid. If at any time the diaphragm were to fail, it opens a path for process fluid to enter into the pilot regulator. In cases where process fluid exposure may harm the pilot regulator, it is advisable to prevent process fluids from entering into the pilot regulator using one of these recommended methods.

- Check valve: Placing a check valve in the line between the pilot regulator and the BPR will prevent process fluid from entering the pilot regulator. In this case, a small bleed on the order of 0.002” will need to be added to allow the pilot fluid to bleed when a decrease in pilot pressure is needed. The schematic below shows how to configure the system. This system can be designed in processes at any pressure.

- Detection Sensor: If your process fluid can be easily detected using a device such as a conductivity meter, pH meter, humidity sensor, etc., then this is another way to prevent process fluid from entering the pilot regulator. A small volume above the pilot port can house a detection device and act as a holding space for any leaked process fluid. When the process fluid is detected, a signal is sent to close the solenoid and keep the process fluid in the small volume container. See sketch below. This design works well if the process fluid has characteristics easily detected by a sensor.

- Quick Exhaust: A Quick Exhaust valve is a three-ported valve with one inlet port, one outlet port and a larger exhaust port. When the inlet port is pressurized, the exhaust port is closed, and the inlet port is open to the outlet port. When pressure falls at the inlet of the Quick Exhaust valve, the outlet port is automatically opened to the exhaust. When positioned in the line from the pilot regulator to the BPR, the process fluid from the BPR is diverted out the exhaust port if the diaphragm ruptures. See sketch below. This design works well in process lines with lower pressures, up to 200 psi.

Vacuum Regulator Safety Design Considerations

Equilibar vacuum pilot regulators (EVPs) and fittings are not compatible with corrosive chemicals. The flow from the EVP is from atmosphere to the vacuum pump, so no process gases are entering the EVP in normal operation. (There is always a slight bleed through the EVP). See Figure below. If the process fluid contains corrosive gases, we recommend installing a check valve in the line from the EVP to the vacuum supply pump. When the vacuum pump is turned off, the check valve prevents process gases from bleeding back into the pilot regulator through its outlet.