Equilibar strives to find creative solutions for the most extreme pressure control challenges, including harsh chemistries. We offer wetted body components for our back pressure regulator in stainless steel 316L, stainless 17-4PH, Hastelloy C276, Alloy A20, Titanium, and Zirconium. With this many options, we’re able to meet the chemical compatibility requirements for almost any application.

But what options are available for those rare applications that involve extremely corrosive environments that can’t be addressed with a standard wetted body material?

One intriguing new solution is to apply a protective coating to the metal body of the regulator. Coatings based on tantalum metal are an excellent option for this because tantalum is nearly immune to chemical attack. Moreover, tantalum-coated parts offer the advantages of solid tantalum at a fraction of the cost, making them an especially attractive option.

Tantaline is an international company that specializes in tantalum metal coatings. Its corrosion resistant products outperform titanium, zirconium and specialty nickel alloys such as Hastelloy.

Tantaline partners with leading OEMs and fabricators to apply tantalum coatings to existing standard stainless steel base parts, creating an end product that is ideal for corrosive environments, even those involving high temperatures, pressures and concentrations of chemicals such as hydrochloric acid, sulfuric acid, acetic acid, sour gas and nitric acid. In fact, the resulting parts are the most corrosion resistant products commercially available.

Typically, base parts are stainless steel; however, other materials may be used.

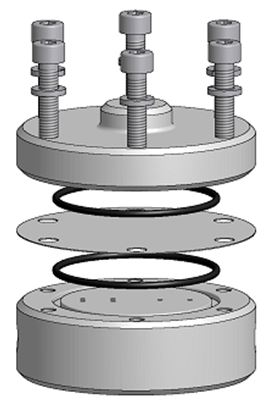

We believe Equilibar’s back pressure regulators are particularly compatible with the tantalum protective coating. Equilibar regulators have only one wetted metal component, which is the main regulator body. The Equilibar does not have any reciprocating shafts, valve members, or pistons because our design uses a flexible diaphragm membrane to both sense the controlled pressure and to directly form the valve seal against a field of multiple parallel orifices. The metal body and the diaphragm are the only two wetted parts. The diaphragm may be constructed of PTFE, glass reinforced PTFE, PEEK, Polyimide, PCTFE, HDPE, Viton, Buna-N, or EPDM as required by application requirements.

Visit Tantaline’s website at http://www.tantaline.com/

Explore other options for back pressure regulators that resist corrosion from harsh chemistries

contact an application engineer at Equilibar inquiry@equilibar.com . We are excited about this opportunity and welcome your questions and feedback.