Equilibar back pressure regulator body components and metallic diaphragms can be treated with an inert silicon coating. The Siliconert® surface treatment by Silkotek eliminates surface adsorption of active compounds like sulfurs, H2S, ammonia and mercury on steel. This surface treatment process allows users to install Equilibar® regulators in systems with low level sampling and storage of active compounds.

For increased wear resistance, Dursan® coating can be applied. Dursan’s superior inertness and extreme corrosion resistance make it the ideal coating for harsh environments found in applications such as:

- Chemical process industries,

- Refining,

- Oil & Gas exploration

and other demanding applications.

Equilibar back pressure regulators in SS316 with no coating (top), Siliconert® coating (bottom left), and Dursan® coating (bottom right)

Performance data was taken using a PTFE coated glass composite diaphragm and Polyimide diaphragms between all three units. The pressure control performance was stable from unit to unit. Results indicated that the thin micron layer of inert coating caused no degradation in the high precision capabilities of the Equilibar regulators tested.

Stainless Steel 316 diaphragms are also available for coating.

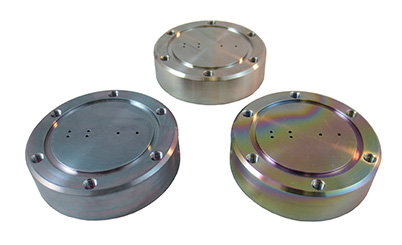

SS316 diaphragms with no coating (top), SilcoNert® 2000 coating (bottom left), and Dursan® coating (bottom right)

The back pressure regulators is composed of a wetted body and non-wetted reference cap. The non-wetted metal caps are provided without the silicon inert coating but are available with the sulfur resistant coating upon request.

Equilibar BPR with wetted components coated with inert silicon for sulfur, H2s resistance. Non-wetted metallic parts without coating.

For more information on Inert Silicon Coated Back Pressure Regulator or Inert Silicon Coated Diaphragms please contact Equilibar.

Contact an Engineer