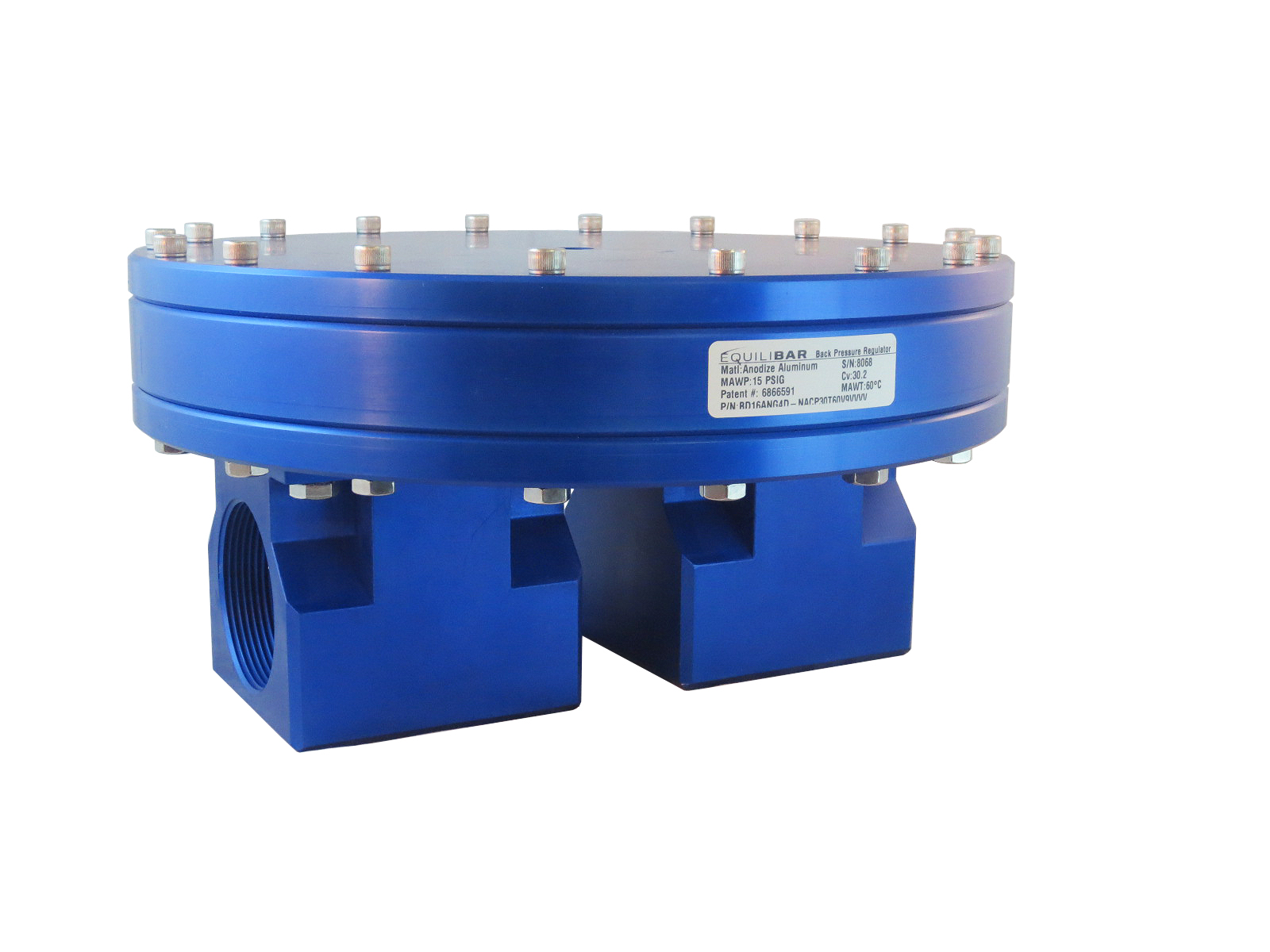

Equilibar’s line of high accuracy and high flow vacuum regulators have been available only in stainless steel 316 or in PVC plastic. Now Equilibar is offering it’s vacuum regulator designs in durable and lightweight anodized aluminum. This aluminum construction offers lower cost than stainless and superior durability over the previous PVC models.

Aluminum Vacuum Regulators Offer Performance Advantages

For most industrial vacuum applications anodized aluminum is an ideal material. Aluminum is lightweight, rugged, and is corrosion resistant. Equilibar vacuum regulators use a different design than standard industrial regulators to control vacuum pressures more accurately. This design allows the vacuum regulator to have higher peak flow rates while maintaining a stable accurate vacuum. Until recently this vacuum regulator design was only available in stainless steel 316 or in PVC plastic. Offering this regulator design in anodized aluminum creates a less expensive option for economy sensitive OEM or high volume installations.

Why Equilibar Vacuum Regulators Are More Accurate

Equilibar vacuum regulators use a large sensitive diaphragm as the only moving part. This unique design controls vacuum by allowing the diaphragm to directly seal against a field of multiple parallel orifices. The diaphragm is both the vacuum sensing element and the valve. The Equilibar design eliminates the internal friction of traditional vacuum regulators that use a spring loaded diaphragm to modulate a sliding valve shaft. The multiple orifice design offers the advantage of wide flow rate capability as a single small orifice is utilized for low flow conditions and additional orifices are instantly brought into play as required when the system flow rate increases.

Manually and Electronically Controlled Vacuum Regulator Options

Manually adjustable and electronically controlled vacuum regulator models are available. The Equilibar design is a pilot operated vacuum regulator. The vacuum is regulated in a precise 1:1 relationship between a pilot set point vacuum and the vacuum on the main inlet port connection. The pilot vacuum may be applied using either a manual knob adjusted vacuum regulator or with a high resolution electronic vacuum regulator. The manually operated pilot regulator may be located remotely from the HV in a location that is more convenient or safer for the user. The electronically controlled option is available in traditional 0-10VDC or 4-20mA analog or in RS232/485 or Ethernet IP serial digital communications. The electronic and manual pilot regulators are easily swapped in the field so an application may be initially installed with a simple manual control and later upgraded to an electronic control.

Vacuum Regulator Wetted Material and Port Size Options

Equilibar aluminum vacuum regulators are available in line sizes from ¼ inch through 6 inches with the new lower cost aluminum models currently available in ¼ inch through 2 inch port size. Wetted parts are color (blue) anodized aluminum alloy 6061-T6 with Viton 0-rings and your choice of diaphragm material. Diaphragm choices include PTFE, Buna-N, Viton, and HDPE.

Vacuum Regulator Applications Include vacuum molding, vacuum dehydration, and vacuum forming.

“Aluminum alloys are an awesome choice for the industrial workplace” said Equilibar operations manager David Reed. “Equilibar vacuum regulators manufactured from stainless steel have always offered high performance control in applications with high temperatures or corrosive environments such as vacuum distillation. Now Equilibar is making that same great design more affordable through the use of less expensive materials. Industrial clients with high flow vacuum molding applications and OEM’s with large numbers of vacuum pick & place suction cups will now be able to benefit from Equilibar’s more economical vacuum regulators. Additional applications that are a great fit for an affordable vacuum regulator include vacuum extrusion and forming systems, vacuum casting, vacuum molding, and vacuum dehydration”.