The Novartis-MIT Center for Continuous Manufacturing conducts research into the emerging field of continuous manufacturing of pharmaceutical compounds. Dr. Stephen Born, working with Dr. Bernard Trout Group at the Massachusetts Institute of Technology has conducted extensive flow chemistry research using micro-reactors and membrane separation of organics and aqueous phases.

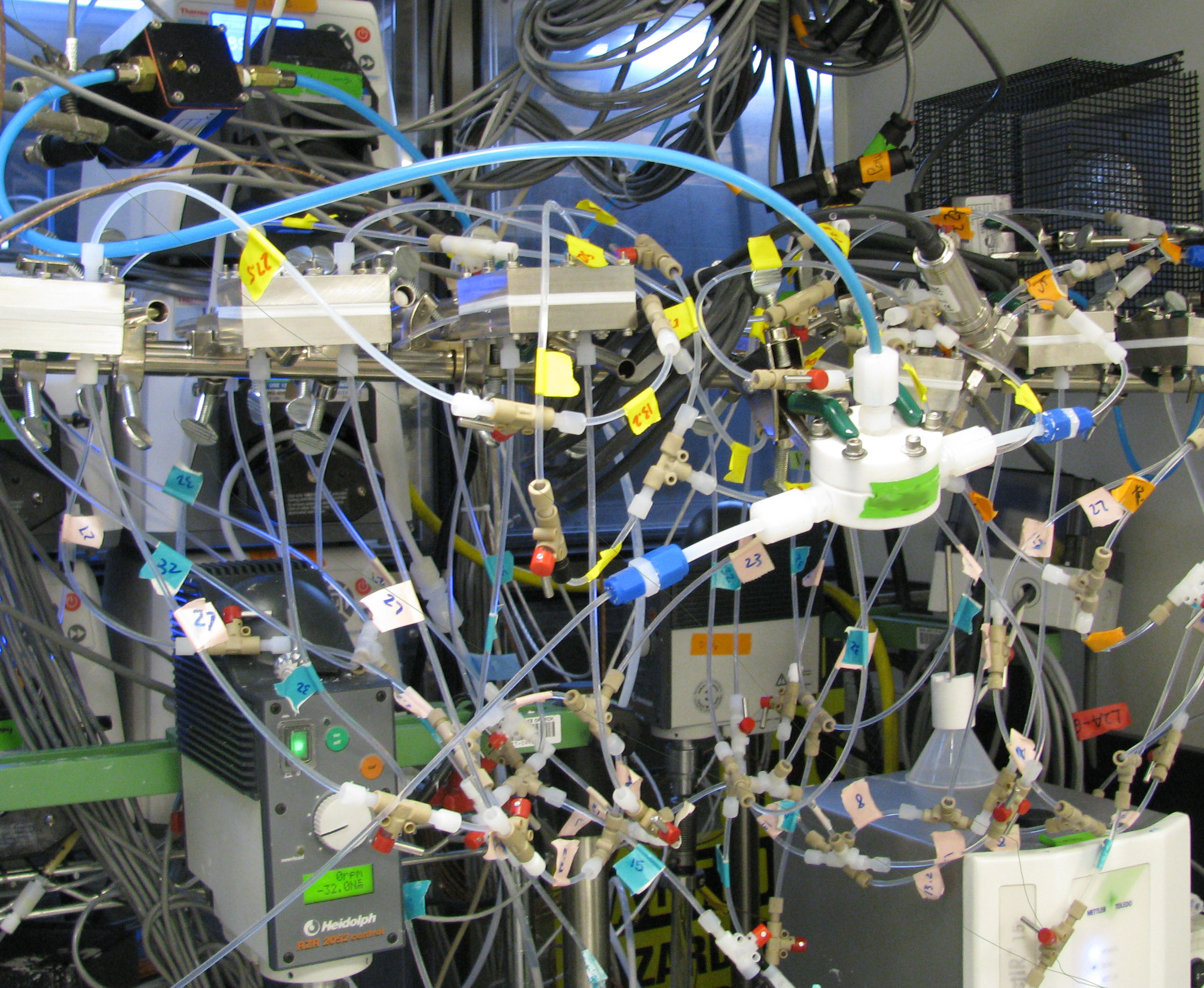

This research has been published in the paper End-to-End Continuous Manufacturing of Pharmaceuticals: Integrated Synthesis, Purification, and Final Dosage Formation. In this research, 12 parallel 1 μm Pall Zelfuor membranes were used to separate micro-reactor products into aqueous and organic phases. As documented in the supporting information, a single Equilibar 1/4″ PTFE back pressure regulator was used to control the merged aqueous membrane outlet streams at a differential pressure 700 Pascals higher than the organic phase.

Equilibar has both 100% PTFE and 100% Hastelloy back pressure regulators available to meet the demanding requirements of continuous pharmaceutical research. These regulators can be used for both flow control and pressure control applications.