Equilibar has published a new case study that focuses on supercritical water gasification research that is being conducted by Brian Pinkard, a PhD student in the Novosselov Research Group at the University of Washington.

Supercritical water gasification is an emerging technology that is useful for multiple environmental efforts. When water becomes supercritical at extremely high temperatures and pressures, it takes on unique physical properties and can be used to destroy hazardous waste, treat sewage, and create fuel from biomass such as animal waste.

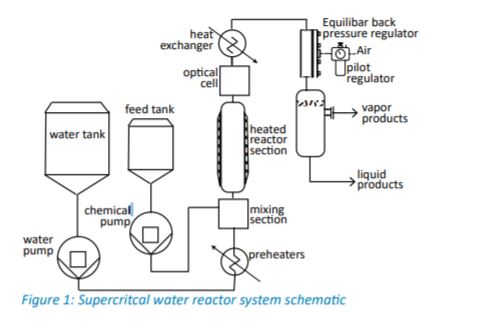

Supercritical water gasification has been studied in depth in the laboratory setting using small batch style reactors, but less research has been done using more commercial continuous flow type reactors that would be used in real life scenarios. Pinkard is working to design and fabricate a continuous flow reactor for the destruction of chemical waste.

Supercritical water reactors rely on back pressure regulators to achieve precise pressure control within the reactor. Typically, the regulator operates in tandem with a constant mass flow rate pump at the front end of the system to supply pressure. For research purposes, precise pressure control is critical to accurately study chemical decomposition rates. It is especially important at low flow rates.

The combination of high temperature, high pressure and accuracy at low flow rates are what led Pinkard and fellow researchers to investigate using an Equilibar® BPR to control the internal pressure of the supercritical water reactor. Equilibar technology offers the unique advantage of providing precise pressure control at extremely low flow rates while also being capable of handling extreme process conditions such as high temperatures and pressures.

Equilibar engineers recommended an Equilibar® U6L Ultra Low Flow Series Precision Back Pressure Regulator with a PEEK diaphragm and Kalrez O-Rings. The U6L Research Series High Pressure Ultra Low Flow Back Pressure Regulator is designed to meet the demanding requirements of research and high pressure reactor control applications. It will hold stable pressure across very wide flow ranges and can handle liquids, gases, or multi-phase mixtures. These regulators will withstand highly aggressive chemicals and can perform at temperatures up to 450 °C.

Equilibar engineers recommended an Equilibar® U6L Ultra Low Flow Series Precision Back Pressure Regulator with a PEEK diaphragm and Kalrez O-Rings. The U6L Research Series High Pressure Ultra Low Flow Back Pressure Regulator is designed to meet the demanding requirements of research and high pressure reactor control applications. It will hold stable pressure across very wide flow ranges and can handle liquids, gases, or multi-phase mixtures. These regulators will withstand highly aggressive chemicals and can perform at temperatures up to 450 °C.

For more details and data, read the case study or contact one of our experienced application engineers.