Metal Organic Frameworks (MOF) are a class of nanomaterials with high surface areas and porous structures that offer potential advantages for a variety of applications including hydrogen storage, water purification, and wound healing. Despite their promise, MOFs have not achieved widespread use due to a lack of large-scale manufacturing synthesis processes.

Researchers in the Mechanical Engineering Department at the University of Washington in Seattle are conducting research to study how the thermodynamics of supercritical fluids impact the synthesis of MOFs. They have found that using a specialty blockage resistant back pressure regulator (BPR) helps with an important step of their research–maintaining stable pressure in a nanomaterial synthesis reactor that is near the critical point of carbon dioxide.

Process Details:

Historically, researchers have faced difficulties adapting MOFs for practical applications because the laboratory processes they use are difficult to scale up for production. In 2020 Elizabeth Rasmussen, then a PhD candidate at the university, published a paper with her colleagues that described an innovative method to scale MOF nanoparticle synthesis using continuous flow supercritical carbon dioxide.*

To eliminate dry ice formation and the blockage it creates as well as improve the production rates of the  reactor, Dr. Rasmussen replaced a traditional spring-loaded regulator with an Equilibar® B6R. The B6R is part of the BR series of specialty BPRs that are specifically designed to be blockage resistant, particularly in supercritical environments.

reactor, Dr. Rasmussen replaced a traditional spring-loaded regulator with an Equilibar® B6R. The B6R is part of the BR series of specialty BPRs that are specifically designed to be blockage resistant, particularly in supercritical environments.

The B6R integrates technology for supercritical applications with a design that maintains high precision control while reducing the Joule-Thomson effect of supercritical process fluids passing through the regulator’s outlet orifices. Like Equilibar’s other patented BPRs, the B6R features a dome-loaded, multiple orifice design with a thin, supple diaphragm that provides superior precision, instantaneous reaction, and frictionless operation.

A key design feature of the B6R and other regulators in Equilibar’s BR series is a downstream expansion cavity that provides a continuously increasing cross sectional area to eliminate convergence points for dry ice build-up during decompression. Specially designed O-ring grooves reduce stress during rapid decompression, which increases O-ring life.

Dr. Rasmussen’s system required an operating pressure up to 6,000 psi to process supercritical carbon dioxide. She and her fellow researchers also wanted to remove a particle filter so that nanoparticles could be collected in a flask downstream of the BPR. To meet these requirements, Dr. Rasmussen worked with Equilibar engineers to select a B6R with a PEEK diaphragm and Kalrez® O-Rings. The B6R delivered a pressure accuracy of ± 2 %. A nitrogen gas cylinder was used to supply the pilot setpoint to the dome-loaded BPR.

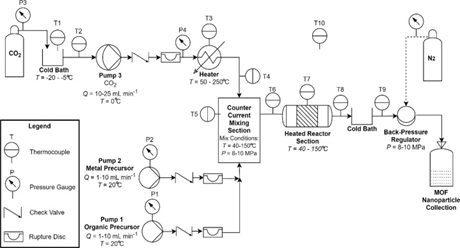

The schematic shows the supercritical carbon dioxide reactor system with the Equilibar BPR downstream of the reactor providing precise, consistent pressure control.

A video walk-through of the laboratory reactor and demonstration of the back pressure regulator operating can be seen in a YouTube video titled, “Synthesis of metal-organic framework (MOF) via continuous flow supercritical carbon dioxide reactor”

Read the entire case study here, or, for more information about the entire BR series of blockage resistant regulators, visit Equilibar’s supercritical BR page.

Specialty Regulators from Equilibar

The B6R blockage resistant regulator is one of several specialty regulators from Equilibar that feature designs for specific process needs such as extreme temperatures, harsh chemistries, and extreme pressures. Equilibar also offers single use valves and other sanitary fluid control devices for biopharma processes and even an alternative regulator to replace the discontinued Grove Regulator Company’s Mity Mite BPR for legacy processes that still require an exact drop-in replacement.

In addition to back pressure regulators, Equilibar offers unique fluid control devices for vacuum and flow control applications that feature the same dome-loaded multiple orifice design. Custom designs are available for each of these devices, making the possible configurations almost limitless.

Equilibar’s expert application specialists have experience with a wide range of challenging fluid control applications. Please don’t hesitate to contact them about any back pressure, flow control or vacuum control challenge. They look forward to hearing from you!

* References:

[1] E.G. Rasmussen, J. Kramlich, I.V. Novosselov, Scalable Continuous Flow Metal–Organic Framework (MOF) Synthesis Using Supercriti[1]cal CO2, ACS Sustainable Chemistry & Engineering 8(26) (2020) 9680-9689. LINK

[2] E.G. Rasmussen, J. Kramlich, I.V. Novosselov, Synthesis of metal-organic framework HKUST-1 via tunable continuous flow supercritical carbon dioxide reactor, Chemical Engineering Journal 450 (2022) 138053. LINK