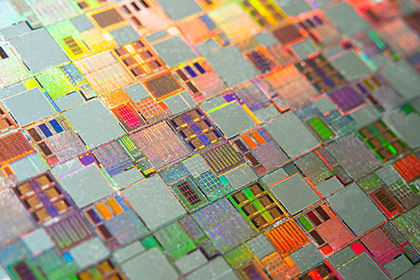

While digital technology has evolved at a brisk pace for decades, multiple factors are in play to make the coming year especially significant for the semiconductor and microchip industries. The CHIPS and Science Act was signed into law in August 2022 and will provide roughly $280 billion in new funding to boost research and manufacturing of semiconductors in the United States. At the same time, semiconductors and microchips play an essential role in the stunning adoption of artificial intelligence and machine learning that is happening all around the world. Finally, smart technology continues to be rapidly integrated into more and more devices that people use in their daily lives.

Manufacturing of semiconductors and microchips is a complex process that takes place in highly specialized environments, with pressure and vacuum regulation playing a key role in several steps. The foundational direct-sealing diaphragm technology behind Equilibar precision back pressure regulators (BPRs) and vacuum regulators (EVRs) is especially useful for a variety of semiconductor fabrication processes because of its extreme accuracy, fast response and versatility for handling specialty gases.

Equilibar’s new semiconductor application page focuses on specific steps in semiconductor fabrication that could benefit from Equilibar® valves’ direct-sealing diaphragm technology.

Pressure control in inert gas delivery systems

Semiconductor manufacturing requires inert high-purity gases to protect the fragile wafers on which electronic circuits are created. In addition to operating at tight pressure and flow specifications, a well-designed inert gas system is safe, easily automated, and easy to maintain. The unique Equilibar design with a flexible diaphragm as the only moving part allows the BPRs to be extremely accurate and responsive, especially in automated applications. A variety of sizes and custom designs are available.

Vacuum holding for semiconductor wafers

Sensitive vacuum tables are used to hold semiconductor wafers in place during inspection or other processes. Vacuum table applications often pose a difficult pressure control challenge because flow rate fluctuates rapidly, which could cause an unregulated system to fluctuate in vacuum pressure. This could result in changes to suction force, which can cause damage to the sensitive parts. The Equilibar vacuum regulator is designed to immediately open or close when it senses a disturbance in flow, resulting in precise vacuum table pressure control. In addition to vacuum holding, Equlibar EVRs are used in vacuum packaging of products and pick and place suction cup control. In pick and place control, the EVR reaches the desired suction pressure quickly, immediately compensates for different pick and place modules coming on and off line, and remains on target if a plunger misfires.

Other semiconductor-related applications in which Equilibar products can be useful include deuterium gas control for semiconductor annealing, corrosive etchant flow control in lithography and imaging chamber pressure control.

More detailed information and schematics can be found on our Semiconductor Fabrication Application Page.

Equilibar engineers have both experience and expertise in addressing complex, demanding pressure and vacuum control challenges. If you have an application in the semiconductor industry that requires fluid control, please contact our engineers to discuss your application. They look forward to hearing from you.