During the past year, Equilibar engineers have noticed an uptick in inquiries from researchers looking for better ways to control back pressure in fuel injector test stands. One reason for the renewed interest is that scientists around the world are exploring ways to use hydrogen as a green fuel enhancement for combustion engines.

Background

Fuel injection systems are used to precisely add fuel to combustion engines in an efficient and controlled manner. Fuel injector test stands are used to conduct research and development on these systems as well as quality control.

Fuel injector test stands or test benches typically involve controlling the pressure upstream and downstream of fuel injectors. Controlling both ensures that the system outputs the desired flow with a given pressure differential. Upstream pressure is usually provided by a high-pressure fuel rail with a pressure reducing regulator.

On the downstream side, a back pressure regulator (BPR) may be used on each injector to test them all for a variety of discharge pressures or on a shared accumulator if they are all being tested at the same discharge pressure.

Back pressure control details

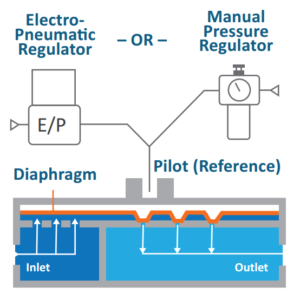

Fuel injector test stands benefit from back pressure control that responds immediately and is easily automated. Direct-sealing diaphragm technology is capable of adeptly handling both of these challenges. Unlike traditional back pressure regulators, these BPRs use a novel design in which a diaphragm covers a field of parallel orifices located in the body of the regulator. As fluids flow through the unit, the diaphragm lifts off the orifices to release pressure. When flow is minimal, only a portion of one orifice opens to release the pressure. When flow is high, the diaphragm is pushed up to engage all the orifices. This design responds immediately to changing conditions and setpoints.

Direct-sealing diaphragm BPRs are dome-loaded and pilot-operated, which means that the pressure of the fluid fed to the dome is set by a second regulator called a pilot regulator. For computer-automated applications, an electronic pressure regulator takes the input signal from the computer and translates it into pressure that is fed to the dome.

Additionally, the wide Cv range and ability to maintain stable pressure control with mixed phase liquid-gas flow allows these regulators to be used in systems that would normally require 2 or more control valves to cover a similar range. In terms of material compatibility, the simple design with a diaphragm as the only moving part allows customization of diaphragm and O-ring materials to match each application’s chemical compatibility, temperature, and pressure requirements.

Pressure control for hydrogen fuel injector test stands

As concerns about global warming and fossil fuel dependency rise, research into hydrogen fuel has accelerated. Some of the studies involve using hydrogen fuel enhancement for internal combustion engines. By injecting high pressure hydrogen into a diesel or natural gas engine, both an increase in fuel economy and significant reduction in CO2 emissions can be achieved.

Direct-sealing diaphragm BPRs work just as well for hydrogen injector test stands as they do for traditional fuels, making them a good fit for this exciting work.

BPRs for the most challenging applications

Equilibar offers a full range of these patented BPRs, and our engineers are experienced in selecting the best design for each application. Equilibar products have also been successfully used for other aspects of hydrogen energy including pressure control for electrolysis and fuel cell testing.

See our fuel injector test stand pressure control application page for more detailed information including schematics.

As always, we hope you will contact one of our experienced application specialists with questions about your particular fluid control challenge.