For years, Equilibar’s direct-sealing diaphragm technology has been popular among scientists and engineers working in cryogenics. Historically, Equilibar’s cryogenic applications have included work in radio astronomy, pharmaceuticals and aerospace products. More recently, our engineers have reported exciting new cryogenic applications related to cryogenic fuel pump testing for rockets and liquid hydrogen storage for green energy technologies.

Cryogenic Fluid Control Basics

Cryogenic technology deals with the use and study of materials at exceptionally low temperatures, typically below -150°C. At these cryogenic temperatures, common gases such as Nitrogen and Helium change phase from gas to liquid and can then be used to keep other material frozen such as food, tissue samples and electronics. Temperature and pressure of these liquids play an important role in how they can be used successfully.

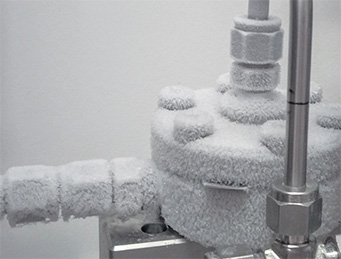

In any cryogenic fluid system, controlling pressure can be difficult because the seals used by many traditional control valves become brittle at temperatures this low. The simple design of Equilibar back pressure regulators (BPRs), utilizing only a flexible diaphragm and a seal on the circumference of the body, gives some flexibility in options for cryogenic service compared to traditional stem-based valves.

Cryogenic Pump Testing

Equilibar back pressure regulators (BPRs) are commonly used in the automotive and aerospace industries to simulate system load on pump test stands, generally using gasoline, diesel or transmission fluid.

The process of testing pumps for use with liquid oxygen or hydrogen, which are used to fuel rockets, is similar but involves much more challenging cryogenic conditions.

In systems like these, using high pressure BPRs like the Equilibar H6P with spring-energized seals has allowed customers to utilize the wide Cv range and high accuracy of the Equilibar technology in extreme conditions that are generally impossible for most traditional valves. The 1:1 dome-loaded control of Equilibar technology easily automates the system with an air/nitrogen pilot pressure and electronic pilot regulator.

Cryogenic Storage Head Pressure Control

Cryogenic liquids must be stored in multi-walled vessels insulated from the outside environment with vacuum in the annular space (similar to a thermos). While these containers are well insulated, a small transfer of heat from the surrounding environment is unavoidable, causing some of the fluid to boil off and create a gas “head” above the surface. Relief valves or back pressure regulators are often used to control this gas head pressure by venting pressure as needed to ensure the vessel does not fail and the fluid in the tank does not completely boil off. These systems are similar to tank blanketing or padding.

Liquid hydrogen storage is of heightened interest for the green energy industry because hydrogen can be more easily stored and transported in its liquid form. The pressure of the tanks involved in these situations varies greatly based on the specific use and size of the vessel. Equilibar BPRs with PTFE or PEEK diaphragms and spring-energized seals have both been successfully used at near atmospheric pressures or up to 10,000 psig.

More Information on Cryogenic Fluid Control

We invite you to visit our updated cryogenic fluid control page, which has technical details on both cryogenic pump testing and cryogenic storage head pressure control as well as other challenging low-temperature applications. And, as always, our application specialists are eager to hear about challenging fluid control scenarios. Please feel free to contact them with your questions and comments.