Equilibar’s EVR vacuum regulators feature an inherently fast-reacting design that automatically compensates for changes in flow rate. They offer multiple advantages over traditional vacuum control valves that typically rely on an external control loop and I/P actuator.

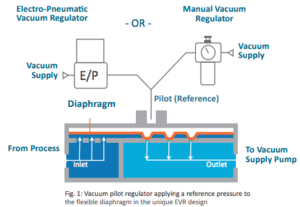

Unlike traditional valves, the Equilibar vacuum regulator uses a pilot operated design with a flexible diaphragm as the only moving part. This means that a pilot setpoint vacuum pressure signal is applied to the top of the diaphragm. Once the system’s vacuum level equals the pilot setpoint, the diaphragm becomes balanced over a field of orifices. Flow rate is automatically limited to the amount required to keep the system vacuum pressure equal to the pilot setpoint.

If the flow rate into or out of the system suddenly changes, the diaphragm will instantly move to match the new flow rate, keeping the vacuum at the desired setpoint. This occurs because the pilot pressure on top of the diaphragm does not need to change to move the diaphragm into the new position since the pilot pressure is at the desired setpoint already.

The pilot setpoint can be applied with a manually controlled regulator or an electronic vacuum pilot regulator.

The Problem with the Traditional Approach

In contrast, many traditional systems use a flow control valve with an actuator driven by an I/P converter. Often a control loop modulates the flow control valve, but it is too slow to allow the vacuum pressure to remain steady when the flow rate changes abruptly. Any sudden change results in a dramatic vacuum pressure spike. In many cases, the disturbance in the system has already passed before the control valve has responded.

Instantaneous Control

The Equilibar vacuum regulator’s instantaneous vacuum control offers a faster response time. For more information and schematics, visit our High Speed Vacuum Control page, contact one of our engineers, or watch the demonstration of this concept in our Equilibar Engineering Lab.