Every March, Equilibar focuses on the impactful role our research customers play in our daily work.

The tradition began as a spinoff from our lively interoffice bracket contest for March Madness, aka the NCAA men’s basketball tournament. We began making a list of participating universities where we have customers and cheering for them in addition to our personal favorites.

We’re excited to report that in this year’s tournament, we have customers at a record 31 of the 68 universities competing! We look forward to following them to the Final Four match-up.

A snapshot of emerging technologies

In recent years, Equilibar has also used March Madness as a reminder to do an annual review of scientific journals that have cited our technology. It’s always both exciting and gratifying to see the variety of work depicted in these papers.

“Looking back over my years at Equilibar, I can say that working with brilliant, forward-thinking scientists is truly one of the best parts of my job,” noted Equilibar founder Jeff Jennings. “There’s something almost magical about collaborating with them. At times it’s not clear how information will be used, but out of the collective global effort, advances are clearly being made in several important areas. Sometimes it happens slowly, but other times it’s surprisingly fast. It excites my imagination to see what new fields will benefit from using our technology in the coming years.”

According to a casual survey of research databases, Equilibar has appeared in approximately 100 scientific papers since last year’s tournament. The following are just a few examples of fields in which Equilibar® valves and regulators have been used to develop disruptive technology during the past 12 months:

Aerospace

February 2022 Journal of Terramechanics : Experimental evaluation of cone index gradient as a metric for the prediction of wheel performance in reduced gravity – ScienceDirect (full text available)

From protective tile installation on the Orion spacecraft to acoustic testing of the James Webb Space Satellite, Equilibar has been involved in a wide range of aerospace applications. This paper about developing reliable planetary rovers is yet another exciting example. The paper reports that “One of the major challenges faced by planetary exploration rovers today is the negotiation of difficult terrain, such as fine granular regolith commonly found on the Moon and Mars.” An Equilibar QB4 digital pressure regulator was used to control pressure in pneumatic cylinders, which in turn controlled vertical wheel loading.

An additional recent aerospace study investigating a new gas cell to enable spectroscopy in harsh planetary conditions is described here:

July 2021 Journal of Quantitative Spectroscopy and Radiative Transfer Demonstration of a uniform, high-pressure, high-temperature gas cell with a dual frequency comb absorption spectrometer – ScienceDirect

Green manufacturing

May 2021 Journal of the American Chemical Society Unifying Concepts in Electro- and Thermocatalysis toward Hydrogen Peroxide Production | Journal of the American Chemical Society (acs.org)

Equilibar has been involved in numerous efforts to develop processes that will reduce the pollution and waste that have traditionally been involved in manufacturing. This paper in the Journal of the American Chemical Society describes research into a method of reducing the impact of chemical oxidations in the manufacturing of hydrogen peroxide. Hydrogen Peroxide is used throughout the chemical industry as an environmentally friendly oxidizing agent, but the traditional method for its production requires significant energy consumption and also generates waste. One of Equilibar’s low flow valves was used in research into the direct synthesis of hydrogen peroxide to reduce environmental impacts of chemical oxidations.

Biofuel

December 2021 Green Chemistry Elucidation of reaction network and kinetics between cellulose-derived 1,2-propanediol and methanol for one-pot biofuel production – Green Chemistry (RSC Publishing) DOI:10.1039/D1GC03650E

Renewable energy is an active area of environmental research. One important piece of the renewable energy puzzle is how to create user-friendly biofuel from biomass, which refers to plant-based materials such as agricultural and wood product residues. The above article describes research addressing the challenge of developing “reaction conditions that can upgrade all fractions of lignocellulosic biomass in a single stage reactor.” The objective is to “better understand the fundamental reaction pathways and kinetics.” An Equilibar back pressure regulator was used to maintain system pressure.

Other interesting biofuel papers can be found in these recent studies from other scientific journals:

March 2022 Bioresource Technology Aqueous phase reforming of birch and pine hemicellulose hydrolysates – ScienceDirect.

January 2022 Journal of Analytical and Applied Pyrolysis: Co-pyrolysis of torrefied biomass and coal: Effect of pressure on synergistic reactions – ScienceDirect (The Equilibar BPR’s thermal capabilities played an important role in this green energy research.)

Supercritical research

July 2021 Journal of Supercritical Fluids: Flash hydrolysis of yeast (Saccharomyces cerevisiae) for protein recovery – ScienceDirect (with accessible schematic)

July 2021 Journal of Supercritical Fluids: Flash hydrolysis of yeast (Saccharomyces cerevisiae) for protein recovery – ScienceDirect (with accessible schematic)

Supercritical fluids are fluids taken to extreme temperatures and pressures above the critical point. In this state, they exhibit unique properties so that distinct liquid and gas phases do not exist. Supercritical fluids are used for dissolving, destroying, extracting, transporting and researching a number of substances. While supercritical technology offers promise, it is not surprisingly full of challenges related to the high pressures involved. Equilibar has provided precise pressure control for a variety of supercritical studies, including this research into recovering protein from yeast.

Flow Chemistry for continuous pharmaceutical manufacturing and other processes

January 2022 Chemical Engineering Research and Design Automated and continuous synthesis of drug substances – ScienceDirect (full text accessible)

January 2022 Chemical Engineering Research and Design Automated and continuous synthesis of drug substances – ScienceDirect (full text accessible)

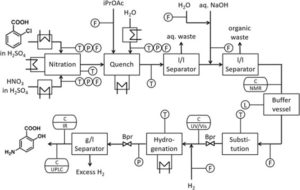

In continuous flow chemistry, two or more reagents are mixed in a continuous manner through a reactor with flow, temperature and pressure controlled so that the desired chemical reaction can take place most efficiently. Advantages of flow chemistry over batch style reactions include more consistent quality, increased efficiency and easy scale-up from R&D to production. The pharmaceutical industry in particular has found the advantages of continuous flow chemistry to be beneficial. In this study a synthetic process was developed integrating nitration, substitution and hydrogenation reactions into one single continuous line, together with liquid/liquid separations and auxiliary chemical unit operations. Using this approach, the Active Pharmaceutical Ingredient was synthesized with all reactions in a single continuous flow stream. Two BPRs were included in the design.

Carbon capture

April 2021 Greenhouse Gases: Science and Technology Sealing of fractures in a representative CO2 reservoir caprock by migration of fines – Rod – 2021 – Greenhouse Gases: Science and Technology – Wiley Online Library (full text available)

April 2021 Greenhouse Gases: Science and Technology Sealing of fractures in a representative CO2 reservoir caprock by migration of fines – Rod – 2021 – Greenhouse Gases: Science and Technology – Wiley Online Library (full text available)

Carbon Capture & Storage involves technologies that reduce carbon dioxide emissions by catching and containing the CO2 created by fossil fuel combustion before it is released to the atmosphere. These technologies have the potential to mitigate climate change by reducing the negative environmental effects of burning fossil fuels. This study examines fines migration–the movement of fine sediment—as a means of plugging oil and gas wells being used for CO2 storage. Like many carbon capture and related research efforts, this experiment used an Equilibar H3P research series regulator designed to handle high pressures.

For more exciting research citing Equilibar, search popular databases of scientific journals such as Elsevier, Royal Society of Chemistry, and Google Scholar. Please note that some of the articles described above require a subscription service to scientific journals for full text access. Contact your institution for more information.

Be sure to follow our social media for updates on how our customer universities are doing in this year’s March Madness. And, as always, we encourage you to get in touch with one of our experienced application engineers about your specific fluid control challenge.