Water-for-injection (WFI) point-of-use (POU) control systems provide temperature controlled water to specified locations in a biopharma processing plant. Point-of-use systems are typically set up in a distribution loop with individual dispensing locations where the process necessitates them. Currently, POU delivery methods mainly use level measurement and mass measurement to collect the desired WFI amounts, and require operator oversight during dispensing. A newer option for WFI delivery is flow measurement which can streamline cleanroom processes. An Equilibar® single use SDO valve, the first single use valve of its kind, can deliver accurate flow control for this WFI operation.

Why are new methods needed for WFI point of use control?

Radar, used to measure level, is low maintenance but typically attaches to the single use bag and struggles with varying bag geometries as the bag fills. Additionally, diffraction of the radar in the media can cause inaccuracies and requires calibration.

Mass measurement using a load cell is accurate, but scales are expensive to purchase and to calibrate. They also take up a large space in the cleanroom. Scales are not portable because they require recalibration when moved, and if the bag is not centered, the scale accuracy can be affected by uneven mass distribution.

In continuous manufacturing operations and cell & gene therapy modalities, there is a focus on optimizing cleanroom space and reducing hold bags and break steps. There is also an effort to make WFI “on-demand” accessible for flexible system needs. Therefore, in addition to accuracy, compact portable WFI delivery methods are becoming important.

Equilibar’s single use flow control solution for WFI point-of-use offers compact footprint, portability and flexibility. Additionally the Equilibar solution can pre-set and automate the desired dispensed amount, reducing labor costs. Calibration requirements of the flow control system are less frequent than those of scales, reducing maintenance costs.

Flow control for WFI POU – How it works

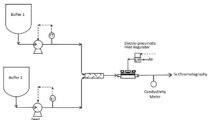

A single use flow control system uses an Equilibar single use valve in conjunction with an Endress + Hauser (E+H) Promass U single use flow meter and a PID controller for automated flow control.

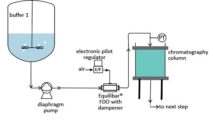

The schematic below outlines a flow path for WFI flow control. Incoming WFI establishes pressure at P1. Fluid moves through the Promass U flow meter FT, which generates a signal. The PID controller compares the FT value to the setpoint and adjusts the signal to the pilot regulator on the Equilibar single use valve. PR is adjusted according to the following setup:

- If Flow > Setpoint, then PR increases

- If Flow < Setpoint, then PR decreases

- To close the valve, set PR > P1

The way the Equilibar valve operates, the reference pressure on the dome is very close to the inlet pressure P1 at most operating conditions.

Single use WFI Point-of-use flow control schematic

Ryan Heffner, Equilibar Single Use Technology Manager, previewed the single use WFI point of use flow control system at Interphex 2024 in a live presentation. Link to the presentation pdf here.

Request a Quote Download BrochureVisit the Single Use Product Page

Rendering of a single use flow control system from WFI point-of-use using an Equilibar SDO valve and E+H single use flow meter.