Watch the video below of how the Equilibar Back Pressure Regulator works.

How Equilibar Back Pressure Regulator Works

Back pressure control valves can be used to ensure that vessel pressure does not exceed the rating of rupture discs. Especially in large vessels with lower pressure ratings, it can be very difficult to control system pressure to avoid losing expensive rupture discs. The addition of a precision back pressure control valve can quickly vent out excess fluid or gas, keeping the process in the needed operating range.

Equilibar’s BD and HV Series back pressure valves offer precision through a wide range of pressure and flow rates. Whereas the BD can be rated up to 250 psig, the HV Series is designed for lower pressures below 15 psig. Both Series can control pressures below 1 psig.

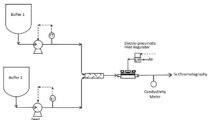

An Equilibar back pressure control valve is used to quickly vent excess vessel pressure

In the schematic above, the rupture disc has a nominal pressure rating of 100 psig. However, using a nominal tolerance of -10%, it is necessary to avoid operating the vessel at or above 90 psig. The back pressure relieving valve is set at 85 psig by a separate air pressure regulator. The Equilibar relieving valve is a 1:1 dome-loaded design, and will open rapidly as the vessel pressure approaches 85 psig, and should attain full capacity around 87 psig.

It is important to note that Equilibar’s products are not rated as safety relief valves and therefore cannot be used without either approved rupture discs or safety relief valves.

Learn more about Equilibar’s pressure valves, or contact an application engineer to discuss your unique requirements.

The HV32 4″ back pressure regulator with 150# flanges. Get product information on larger back pressure control valves