A pyrolysis process is a thermal decomposition of materials at elevated temperatures, differing from a combustion process, which is the burning of fuel in the presence of oxygen. Pyrolysis processes have a wide variety of different uses including breaking down heavy hydrocarbons (like in oil refining), reducing organic matter to elemental carbon (producing charcoal), depolymerization, or catagenesis.

What are the benefits of using an Equilibar valve for pyrolysis processes?

Equilibar® research series back pressure regulators (BPRs) are used in a variety of high temperature reactor applications, but pyrolysis reactors are a subset that are particularly well suited to Equilibar technology. These systems are typically very high temperatures — often 400 °C or greater — and often deal with mixed phase flows or solid particles present within the process stream. Equilibar’s high temperature designs using metal diaphragms and either graphite gasket seals (good up to 450 °C) or silver-coated Inconel c-ring seals (good up to 550 °C) are designed for these high temperature systems. For processes which produce solids, the simple design of the Equilibar valve makes cleaning easy and our multi-orifice designs can be more resistant to clogging than traditional single seat valves.

Application Spotlight: Pyrolysis of Natural Gas – Methane

Methane pyrolysis is an increasingly popular means of producing hydrogen because it has a minimal carbon footprint and requires no rare metal catalysts. The ability to use existing natural gas infrastructure to create hydrogen on-site at the point of use also avoids much of the energy consumption and carbon emissions related to compressing, storing, and transporting hydrogen as well.

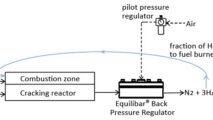

In a methane pyrolysis process, a reactor is generally heated to between 1000 – 1200 °C and methane (CH4) fed into the reactor decomposes into carbon and hydrogen. The solid carbon falls out and 25% of the produced hydrogen is consumed to maintain heat in the pyrolysis reactor by combusting with air.

Pyrolysis reactor with an Equilibar BPR at the outlet to control reactor pressure. Special design can handle high temperature and carbon particulates

An Equilibar BPR may be placed downstream to control pressure within the reactor. Methane pyrolysis reactions generally require low pressure, but the solid carbon produced can be abrasive and easily foul or clog traditional valves. For service in a system like this, Equilibar can provide a hardened steel orifice insert or body to mitigate erosion and construct the valve with either graphite or all metal seals.

Equilibar BPRs are also easily automated by using an electronic pilot regulator to control the reference pressure above the diaphragm. This allows for stable control and remote monitoring without the need for an operator or technician to manually intervene.