When are pulsation dampeners used?

Pulsation dampeners, also called pulsation dampers, are often used in pump systems to reduce damaging pressure surges and therefore keep components functioning well. The Equilibar back pressure regulator (BPR) can be a good choice to reduce pulsations in circulating liquid systems, such as those involving positive displacement pumps, because it offers several unique advantages over traditional BPRs.

Background – How an Equilibar gas-loaded diaphragm regulator damps pulsations

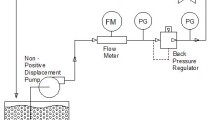

Many types of BPRs can be used to control pump pressure in a loop where a portion of the flow can be returned to the supply reservoir. The outlet pressure of any type of pump can easily be controlled in this manner. Where the pump is a positive displacement type, the higher pressure spikes will be preferentially reduced by the back pressure regulator due to its essential nature.

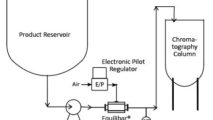

Unlike traditional valves and regulators, the Equilibar BPR uses thin diaphragms loaded with compressible gas, making the device more sensitive to small changes in pressure compared to traditional spring-loaded BPRs. Most Equilibar BPRs are sensitive to pressure changes as small as 0.01% of overall setpoint.

The Equilibar gas-loaded diaphragm also provides a significant pulsation damping effect just upstream of the valve orifice. Traditional pulsation dampers consist of a flexible membrane (typically rubber) with a pre-loaded air charge on the non-wetted side. The Equilibar back pressure regulator provides a similar geometry, allowing the diaphragm to absorb a portion of the pulsations through the close agreement between the wetted fluid pressure and the gas charge pressure.

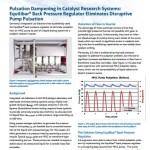

Integrated Lab Solutions addresses pulsation problem with LF Series Back Pressure Regulator

Berlin-based Integrated Lab Solutions, Gmbh (ILS) builds high-throughput test systems for catalyst research around the world. Project Leader Claudia Berger-Karin successfully addressed a critical challenge caused by pulsations coming from an HPLC pump in a liquid reactant injection system. A Bronkhorst CORI-FLOW™ mass flow controller was being used to control the injection, and the HPLC pump was needed only to supply the pressurized reactant. She replaced a spring-loaded back pressure regulator with an Equilibar LF BPR and was able to remove virtually all of the flow variation in the system.

Read Customer Case Study: Pulsation Dampening in Catalyst Research Systems: Equilibar® Back Pressure Regulator Eliminates Disruptive Pump Pulsation

For sanitary applications, the Equilibar FD series of valves and regulators provide sanitary pulsation dampening for processes where shear stresses and pulsations can adversely affect the downstream processing and even damage the process in severe cases.

To learn more about the inner workings of Equilibar’s patented back pressure regulators, see the following detailed video: