Why Equilibar FD Series Regulators are Perfect for Optimizing TFF

The Equilibar® dome-loaded back pressure regulator (BPR) offers higher turndown ratio than other valves, providing precise control across a wide range of flow rates. The flexible diaphragm responds to process changes instantaneously, keeping transmembrane pressure on target. The unique design makes the Equilibar FD a superior choice for optimizing tangential flow filtration (TFF) or cross flow filtration process, delivering faster response for less waste and higher yields.

Our FD series of sanitary BPRs are designed specifically for these applications in which sanitary biopharma equipment must be used. These FD BPRs are made of SS316L and are fitted with USP Class VI diaphragms. They have a crevice-free design and are drainable in certain orientations. The precise and instantaneous control of the Equilibar back pressure control technology make them perfect for optimizing biopharmaceutical filtration.

Sanitary Filtration Highlight: Tangential Flow Filtration

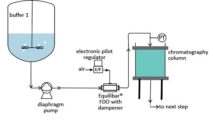

In the filtration system schematic above, an Equilibar FD BPR is used in both the retentate and permeate lines at the exit of the trans flow filtration membrane. A setpoint is established on the dome of the BPR using an electro-pneumatic pilot regulator so the Equilibar FD valve can be computer controlled. This allows the filtration system to be controlled by differential pressure (dP) mode – the pressure differential between the feed and retentate streams or by transmembrane pressure (TMP) mode – adjusts the retentate control valve to maintain constant TMP.

Using FD Sanitary Valves in Flow Control for Flux Mode Filtration Control

If cross flow rate (flux) mode is preferred, flow transmitters may be added to the permeate and retentate lines. In flux mode, flow is maintained by regulating the retentate and permeate flow and the Equilibar FD back pressure regulators would act as flow control valves.

FD Series Sanitary valve designed with ASME BPE standards is top choice for biopharmaceutical filtration

Read more about the Equilibar back pressure regulator technology and how it works.

Contact one of our application engineers to help select the perfect back pressure regulator for your filtration application.

Download Brochure Request a Quote

Watch the video below of how the Equilibar Back Pressure Regulator works.