These columns process streams of critical fluids such as electrolytes, buffer solutions, elution acids, as well as dilute and concentrated drug solutions. These fluids are typically controlled with sanitary control valves or gear pumps, and the flow rate is often measured by expensive Coriolis flow meters to achieve desired accuracy.

Key challenges when processing these fluids include:

- Dosing electrolyte or buffer addition to the column to precisely control pH or concentration. Because these fluids typically have the viscosity of water, one specific challenge is controlling gear pump flow rate at very low flow rates.

- Providing back pressure control on the Chromatography column and Coriolis flow meters to prevent undesired bubble formation.

- Providing good flow control from the very low dosing requirements, while also providing for the high flow rates demanded by the larger system’s Clean-In-Place circulating system.

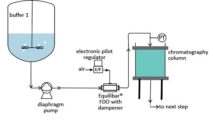

- Eliminating flow pulsations during delivery to the column which can disrupt resin and create channeling that results in inefficient processing.

Contact Equilibar to Discuss Your Sanitary Process

Low Flow Problems with Electrolyte and Buffer Dosing

- Equilibar back pressure regulators are useful for providing necessary back pressure for dosing pumps to prevent pump slip problems at very low dosing flow rates.

- Equilibar regulators can be used as the primary flow control valve to avoid bulky globe valves and extend the flow control turndown range to 100:1 (from 20:1).

Providing back pressure to avoid bubble formation

Bubble formation in Coriolis flow meters or on the resin coated media of a Chromatography Column can cause serious processing problems. Bubble formation can be effectively inhibited by raising the pressure of the fluid in these processes from near atmospheric to the range of 1 atmosphere (1 bar or 14.7 psig) above the gas partial pressures in these solutions. Equilibar back pressure regulators can be installed downstream of these devices to reliably raise the pressures.

Simulating column back pressure when chromatography column is bypassed

Bioprocess system designers often suggest adding a back pressure control valve downstream of the column to mimic column backpressure when the column is bypassed. The back pressure in the bypass line can make transitions from column inline to column bypass and vice versa a lot smoother for the pumps.

Key Advantages of Equilibar® FD Series

The simple compact design of the Equilibar Sanitary Back Pressure Regulator offers several advantages over traditional control valves, including:

- Wide Pressure Range: Design operates with precision from 0.2 bar up to 10 bar

- Wide Flow Range: Operates with 100:1 flow turndown ratio

- Pulsation dampening: Integrated passive dampening is standard

- Ease of Automation: Compact design is automated using remote air pressure regulator

- Simpler Design: One moving part (USP Class VI diaphragm) is simple to clean and maintain

Contact an Equilibar application engineer today to discuss your unique application requirements.

Watch the video below of how the Equilibar Back Pressure Regulator works.

How Equilibar Back Pressure Regulator Works