A pressure bypass valve is essentially a back pressure regulator (BPR). Both control upstream pressure (pressure at their inlet) and function by opening just enough to relieve excess pressure on their inlet port. These devices are referred to by different names based on subtle differences in the application or industry. Equilibar® back pressure regulators are used as bypass regulators in many industries.

Request a Quote Download Brochure

What do back pressure regulators do?

Back pressure regulators control fluid pressure at their own inlet, regulating upstream pressure by opening just enough to hold the desired process pressure. When the pressure at the inlet of the BPR increases above the desired setpoint, the regulator opens up to allow excess pressure to be relieved through the outlet. Conversely, when inlet pressure decreases below the setpoint, the BPR closes to restrict the flow and rebuild the pressure at its inlet.

How does a bypass valve work?

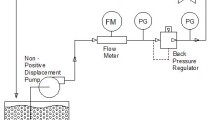

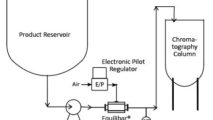

The schematic at right shows a Pressure Bypass Regulator being used to control the pressure at the exit of a pump. The bypass valve allows some fluid to go to the application while the excess fluid bypasses the application and returns to the reservoir. Note that the concept of pressure bypass control works equally well for all types of pumps (i.e. centrifugal pumps as well as positive displacement pumps).

Typical pressure bypass valves use a spring and piston design, and these work well for the most common industrial applications, including traditional hydraulic systems (find traditional pressure bypass valves here). However, there are times when a more sophisticated and accurate bypass valve will be desired. See some examples below.

Precision Pressure Bypass Valves

for Demanding Applications

Equilibar offers a unique back pressure regulator that offers several distinct advantages for pressure bypass applications:

- Extraordinary precision, within 1-2% across wide flow ranges

- Controls across a wide range of flow rates, up to 10,000:1 ratio

- Computer automation using an electronic pressure regulator as the reference setpoint control

- Excellent compatibility with aggressive chemicals and acids

- Compatibility with high temperatures (to 450C)

- Instantaneous response

- Sanitary designs with crevice-free construction and USP Class VI diaphragms meeting ASME BPE

Visit the back pressure regulator product page for more information about available models and sizes.

The Equilibar precision BPRs can provide highly stable pressure control despite widely varying flow rates. Unlike pressure control valves, which typically require several seconds to adjust to changing flow conditions, the Equilibar has lightning fast response (less than 10 mS). When using Equilibar valves, it is possible to rapidly change system pressure and even generate pressure patterns and pulse waveforms.

Equilibar BPRs are sold in sizes up to 4″ pipe size. They can receive their 1:1 pilot setpoint signal from either manual air pressure regulators or from electronic pressure regulators. If needed, custom larger size regulators can be built upon request. Contact us to discuss details.

Contact our engineers for additional information about your application.

Equilibar GS4 1/2″ stainless steel BPR with electronic pilot regulator for automates control