Gradient Elution is a critical step in pharmaceutical production, used to separate biomolecules based on their chemical properties. This process involves blending at least two fluid streams (buffers) to create a precise chemical (gradient) profile that is then delivered to a chromatography column. Blending profiles vary depending on production requirements (e.g., linear or isocratic gradients). The chromatography column contains both useful and waste biomolecules, which must be separated and purified to produce the final product.

Typically, this buffer mixing is achieved by controlling flow rates through separate pumps. A common approach is for one pump to operate at a low flow rate while the other runs at a high flow rate. These streams are combined through a mixer, validated for quality via pH or conductivity measurements, and then introduced into the chromatography column for biomolecular separation or purification. Several factors influence the effectiveness of gradient elution, including:

- Pump flow variations – Flow fluctuations due to pump performance or setup conditions (e.g., push-through flow)

- Gradient delay volume – Lost buffer solution due to time lag in achieving the correct gradient composition

- Chromatography column volume – Governs the total required flow rate for processing

- Flow meter accuracy– Impacts measurement precision and buffer control against desired setpoints

Equilibar back pressure regulator as a flow control valve

Equilibar® back pressure regulators can be configured as automated flow control valves (FCV) to deliver precise blending for sensitive processes. They do this by regulating pressure against the supply source, ensuring smooth, precise flow control with minimal shear. With turndown ratio of 100:1, the Equilibar FCV maintains consistent flow across a wide range of operating conditions and responds instantly to changes in setpoint or upstream process fluctuations. How Equilibar FCV works

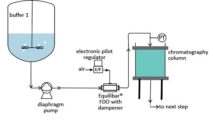

The illustration below shows a typical system setup using the Equilibar FCV. In this example, and in the accompanying video on the right, buffer solutions are in a pressurized state, which can be achieved using elevation pressure or a direct connection to a WFI header.

The Equilibar sanitary FCV functions similarly to traditional pumps in flow control strategies. A controller monitors flow meter feedback and adjusts pilot pressure to maintain the desired flow setpoint. These setpoints integrate into the same control loop that governs conductivity or pH, ensuring compliance with overall chromatography column volume (CV) requirements. As the conductivity setpoint shifts, the flow rate setpoint adjusts dynamically, and the Equilibar FCV reacts instantaneously to maintain process stability—preventing non-conforming fluid from reaching the column.

Conductivity profile accomplished on a benchtop system mixing 1M NaCl and water

5 Key advantages in using Equilibar FCV control strategy:

- Compact footprint – Optimal choice for space-constrained skid designs.

- Flexible installation – The electro-pneumatic pilot regulator can be positioned remotely, reducing complexity at the skid.

- High turndown ratio (100:1) – Accommodates a wide range of conductivity & CV objectives

- Minimal pulsations – Minimizes pulsations and flow variations by regulating against a static pressurized source.

- Simplified system integration – Eliminates the need for dedicated WFI vessels by regulating against a pressurized WFI header.

RELEVANT PRODUCTS

FDO6 3/4″ sanitary valve. Max Cv 4.0

Equilibar SDO3 3/8″ single use bioprocessing valve