Extrusion Control with Vacuum Sizing Box

Many polymer extrusions, such as PVC pipe are made by the use of vacuum sizing boxes to expand the extruded shape onto an external die before cooling. As with positive pressure tubing extrusion applications, it is important to maintain good pressure control to achieve good process control.

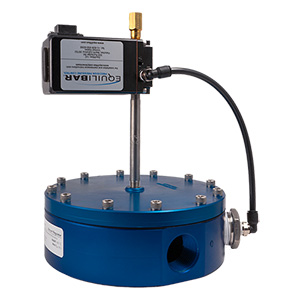

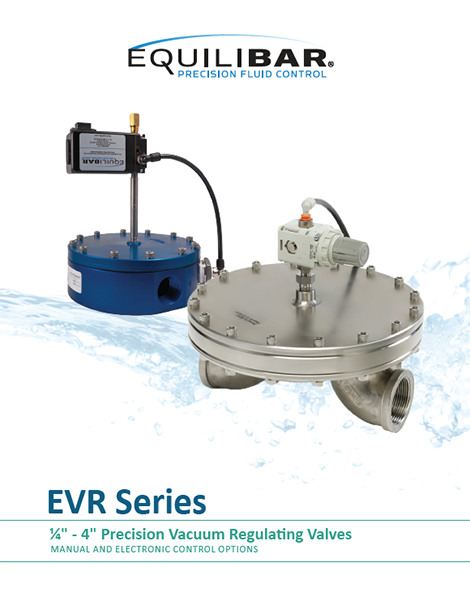

The Equilibar® Vacuum Regulator (EVR) has been demonstrated to improve product quality by tightly controlling vacuum in the sizing box. Equilibar’s Vacuum Regulator uses the same technology as our back pressure regulators, though redeployed into the vacuum range.

To enable process automation, the setpoint signal in the schematic above is provided by an electronic pressure regulator; a manual setpoint regulator would also work in this process.

Learn more about Equilibar’s vacuum regulators.

See also Extrusion positive pressure control application. In positive pressure extrusion applications, air is introduced into the lumen to prevent collapse of the structure while the polymer is cooling. Precise control is needed, especially during disruptions caused during the cutting and clamping of the tubing. In many positive extrusion applications, tubing is produced with multiple lumens.