Equilibar precision back pressure regulators are an ideal solution for limiting the differential pressure across an electrolyzer membrane when the electrolyzer must be brought to atmospheric pressure during an emergency shutdown procedure.

Contact US to Discuss your ApplicationWhy an emergency shut down (ESD) system is important in electrolyzer design

In a production electrolysis system, an emergency shutdown/depressurization procedure may be initiated for a variety of reasons; the goal is to safely bring the system pressure down to atmosphere so that the issue that triggered the shutdown can be addressed. However, a shutdown procedure like this introduces some challenges.

In alkaline electrolyzer systems for example (Figure 1), a thin membrane separates the hydrogen and oxygen sides of the electrolyzer cells. These membranes have limitations in terms of the maximum pressure differential (dP) they can tolerate before rupturing, oftentimes on the order of 10 – 100 mbar.

If the membrane ruptures, the hydrogen and oxygen will intermingle, creating a dangerous mixture of explosive gas. The pressure on both the hydrogen and oxygen sides of the system must be brought down at the same rate to minimize the dP across the membrane. However, that sort of accuracy can be difficult to accomplish with a traditional control valve for several reasons:

- The mass flow rates will vary dramatically between the hydrogen and oxygen lines, given the difference in the weights of each gas

- The initial starting pressure can be rather high, oftentimes over 30 bar, while still requiring accuracy in the tens of mbar

- The gas flows are often wet, with some liquid condensation

- Reliance on closed loop control is not ideal due to the added complexity or explosion hazards

Why choose an Equilibar valve for this Electrolyzer emergency shut down application?

Why choose an Equilibar valve for this Electrolyzer emergency shut down application?

Equilibar® back pressure regulators (BPRs) are a perfect solution for emergency shut-down or blow-down systems in electrolyzers. Equilibar engineers can customize valves (patent pending) that are especially sensitive and precise for this application.

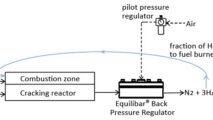

Equilibar BPRs are dome-loaded valves with multi-orifice flow path and a single supple diaphragm to control the pressure. Whatever pressure is applied on the dome of the BPR is the pressure that the valve will control on its inlet. So, a common N2 volume can be connected to the reference pressure port of the BPRs on the hydrogen and oxygen lines to keep the pressure in two lines balanced. That N2 volume pressure can then be let down at a controlled rate, with the BPRs in each line matching that pressure.

- The multi-orifice design of the Equilibar BPR allows for stable control in wide flow ranges. ESD flows will vary widely – starting with high initial flow then gradually tapering off.

- A differential pressure on the scale of tens of mbar can be maintained between the two lines, even with a high initial pressure (30 bar or more)

- Two BPRs can control at the same pressure by using a common volume tied to the domes of each BPR

- The unique design provides for immediate response to process upsets and the BPR can easily maintain pressure of multi-phase fluids (gas & liquid).

Watch our video from the Equilibar lab

Video showing proof of concept of Equilibar Electrolyzer Emergency Shut Down Regulators

Contact An Engineer for more information

Equilibar back pressure regulators are also used in electrolysis process pressure control. Customers find the Equilibar valves to work very effectively for pressure balancing during hydrogen production for many of the same reasons.

IC16 back pressure regulator for precision pressure control in electrolyzer systems

Equilibar BPRs are also used to control electrolyzer pressure in hydrogen production.

Visit our electrolysis page