DCI Test Systems is now offering a back pressure control system that integrates directly with the Equilibar BPR to control pressures up to 20,000 psig. DCI Test Systems has been designing and manufacturing test equipment for core analysis and rock mechanics since 1990. They are excited to collaborate with Equilibar for this new APBR test system.

This system is useful for testing above 5000 psig, pressures at which bottled nitrogen is difficult to obtain. The automated back pressure control system is targeted for core flooding and other core analysis applications.

The DCI system would typically be coupled with an Equilibar UL or HP Series back pressure regulator with flow coefficients up to 0.05. These BPRs are part of our high pressure core test back pressure regulators. Equilibar BPRs can function with precision down to 0 ml/min gas or liquid, easily controlling Cv in the range of 1E-9.

The DCI system shown in the photo at right is built with an Equilibar U20L ultra low flow back pressure regulator made from a Hastelloy C276 body and a PEEK wetted diaphragm and can hold pressures to 20,000 psi.

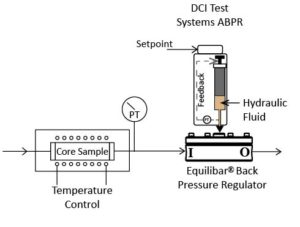

Fig. 1 Internal Feedback Control

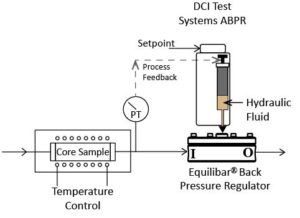

Fig. 2 Process Feedback Control

Contact an Equilibar application engineer to discuss using the ABPR in your core testing system.