In any cryogenic fluid system though, controlling pressure can sometimes be difficult as the seals used by many traditional control valves become brittle at temperatures this low. The simple design of Equilibar BPRs, utilizing only a flexible diaphragm and a seal on the circumference of the body, gives some flexibility in options for cryogenic service compared to traditional stem-based valves.

Generally speaking, the limiting factor for any valve is the elastomer (rubber) seals like O-rings or rubber diaphragms. Many commonly used elastomers have a glass transition temperature in the range of -40 to -60 C, when they become hard and brittle.

For customers needing valves for cryogenic service, Equilibar provides a variety of different options for sealing. Polymer diaphragms made of materials like PTFE, PEEK, or Kapton (polyimide) all perform well even down to 20 K (-253C). For the O-rings, Equilibar valves have demonstrated success using fluoropolymer-jacketed spring-energized seals like the Omniseal line from St Gobain. For low pressures, it is also sometimes possible to use pure PTFE O-rings, although in general the lack of elasticity in PTFE limits the possible use cases. Other options like metal c-ring seals or in some cases removing the O-rings entirely and relying on a metal crush pad seal on the diaphragm are possible as well. Contact Equilibar to discuss your application parameters.

Application Focus: Cryogenic Pressure Control in Radio Astronomy

In 2011, a researcher at The Harvard-Smithsonian Center for Astrophysics was looking for ways to reduce the cryogenic temperature variations in his radio telescope equipment. Astronomical detectors are contained in a cryostat, a device to maintain cryogenic temperatures. The Microwave Kinetic Inductance Detectors (MKIDs) rely on a superconducting strip of metal. As photons from space hit the metal strip, Cooper pairs (pairs of electrons bound together at low temperatures) are split and the inductance of the metal strip changes. A microwave resonator is formed by pairing this with a capacitor, allowing scientists to translate a change in inductance to a measurement of the frequency of the incident photon. Stable temperature control is needed to minimize noise and ensure that the metal remains superconductive.

The traditional method for cryostat temperature control is to circulate helium at about 350 psig and 4 Kelvin from a cryocooler. In this situation, an Equilibar BPR was installed in parallel to allow a portion of the helium to bypass the cryostat and return directly to the compressor. This resulted in more precise pressure control, reducing temperature variability.

The Harvard researcher, Michael J. Smith, published his findings with Equilibar President, Jeff Jennings, in the Proceedings of the ASME 2011 International Mechanical Engineering Congress & Exposition of November 11-17 in Denver, Colorado. The presentation details how the Equilibar BPR was successfully used to stabilize cryogenic temperatures in an astrological sensor by controlling Helium gas pressure in the range of 4 degrees Kelvin. An increase in temperature stability of 66% was reported by the study, which was conducted at the Harvard-Smithsonian Center for AstroPhysics.

A summary of the findings was also spotlighted in Cold Facts Magazine, Winter 2012 edition.

Application Spotlight: Cryogenic Pump Testing

Equilibar BPRs are commonly used in the automotive and aerospace industries to simulate system load on pump test stands. While these systems generally use fluids like gasoline, diesel, or transmission fluid, one particularly interesting use of our valves has been to test pumps used with liquid oxygen or hydrogen for fueling rockets.

Fuel pump test system using an Equilibar BPR to simulate load

In systems like these, using high pressure research series BPRs like the Equilibar H6P with spring-energized seals as described above, has allowed customers to utilize the wide Cv range and high accuracy of the Equilibar technology in conditions that are generally impossible for most traditional valves to operate. Like with any Equilibar BPR, the 1:1 dome-loaded control lends itself to easily automating the system with an air/nitrogen pilot pressure and electronic pilot regulator.

Cryogenic Storage Head Pressure Control

Cryogenic liquids must be stored in multi-walled vessels insulated from the outside environment with vacuum in the annular space (similar to a thermos). While these containers are well insulated, there will inherently be a small transfer of heat from the surrounding environment, causing some of the fluid to boil off and create a gas “head” above the liquid. Relief valves or back pressure regulators are often used to control that gas head pressure – venting pressure beyond a set threshold to ensure the vessel does not fail, while making sure the fluid in the tank does not completely boil off. Systems like these are very similar to tank blanketing or padding.

Cryogenic storage tank with head pressure control using an Equilibar BPR

Liquid hydrogen storage is an increasingly common application within the green energy industry, as large amounts of hydrogen gas can be more easily stored and transported as a liquid. The pressure of tanks like this varies greatly based on the specific use and size of the vessel, but Equilibar BPRs with PTFE or PEEK diaphragms and spring-energized seals can be used equally well at near atmospheric pressures or up to 10,000 psig.

Equilibar back pressure regulators have been used in many other cryogenic and very low temperature applications. For more information, please contact an Equilibar application engineer to discuss your specific process.

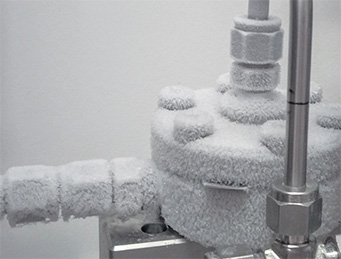

Equilibar BPR in use for a cryogenic application