Flow control for corrosion studies of impurities in CO2

Carbon steel corrodes in presence of carbon dioxide (CO2) and supercritical CO2. When hydrogen sulfide (H2S) or other impurities such as NO2 and SO2 are also present, corrosion rate may increase, and cracking or pitting failures may be a concern. Researchers want to understand the effect of precise impurity levels on a variety alloys to find the best solution for energy sector clients. Steel corrosion studies are performed under carefully controlled temperature and pressure conditions.

Equilibar flow control valves in conjunction with Coriolis mass flow meters provide precision flow control of CO2 mixtures for corrosion studies

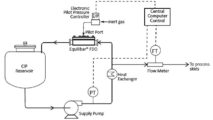

An example setup is shown in the schematic above. A series of pressurized reservoirs are filled with CO2 mixed with various types of impurities for the study. Fluids are delivered at specific rates to an environmental chamber where the corrosion studies take place. An Equilibar® flow control valve combined with a mass flow meter work together to provide the precise ratio of impurities needed for the corrosion study.

Advantages of using an Equilibar valve for this application are its precision control, fast response to changing setpoint needs, and its capacity to operate across a wide range of flow rates in one single valve. Equilibar valves can also be manufactured with chemical resistant materials which is beneficial in this case.

Want to learn more? Contact an Equilibar application engineer for more information.

An Equilibar low flow valve with an electro-pneumatic pilot regulator can be used for flow control in corrosion studies

Pressure control for corrosion studies of supercritical fluids

Supercritical CO2 is used for carbon sequestration, so it is important to understand corrosion properties of piping and transport vessels carrying SCO2. Additionally, turbomachinery design for supercritical CO2 power cycles benefits from understanding corrosion properties of metal alloys.

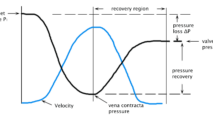

Fluids reach supercritical state at high temperatures and pressures. For effective corrosion studies, reactors must maintain consistent pressure control over a period of exposure time. Equilibar has back pressure regulators capable of controlling the high pressures and temperatures required in supercritical applications. Equilibar also has regulators designed specifically for supercritical use with features that maintain high precision control while reducing the Joule-Thomson effect of supercritical process fluids passing through the outlet orifices.

An Equilibar back pressure regulator controls supercritical test chamber for corrosion testing

Contact an Equilibar application engineer to discuss your application today.