Another method of controlling pump flow is to use a pump with a variable speed drive which in turn changes the flow of the pump.

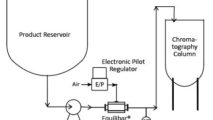

A third method for controlling flow from a pump is to throttle the discharge by opening and closing a valve at the exit of the pump. In the case of controlling the discharge of positive displacement pumps, this technique is used to prevent pump slip (also called pump runaway) and has the added benefit of pulsation dampening. The diagram to the right shows an Equilibar flow control valve in series with a flow transmitter controlling the discharge of a positive displacement feed pump.

Contact Us Back pressure valves Flow Control Valves

In the case of non-positive displacement pumps, throttling the pressure at the pump discharge results in a specific flow rate based on the characteristic performance curve of the pump. This method is described below.

Simple Pump Flow Control for Non Positive Displacement Pumps

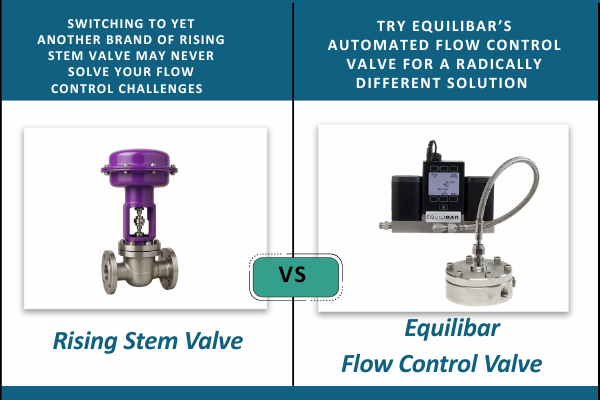

Oftentimes in order to control the flow of a pump, a complicated PID loop is used to electronically control the loop based on the output from a flow meter. The modulating control element is usually either a rising stem flow control valve or a variable frequency drive on the pump’s electric motor. While these methods are a proven way to control the flow of a pump, there are applications where such a setup is not desirable. For example, an aggressive media might require a flow meter technology that is prohibitively expensive. In these cases, a simpler pump flow control circuit using an Equilibar Back Pressure Regulator may be preferred.

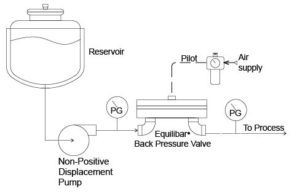

The circuit at the right uses a back pressure valve to set the flow rate coming out of the pump to the process. With a non positive displacement style pump, also called a rotary impeller or a centrifugal pump, the output flow is inversely proportional to the output pressure of the pump. When the output pressure of the pump is low, the output flow of the pump is high. This relationship between pump output pressure and pump output flow is shown on the pump’s flow performance curve, also called a P-V diagram (see graph at right). For every pressure, the pump will only deliver one specific flow rate. Therefore, to control the flow of a centrifugal pump, simply set the output pressure to the point on the P-V diagram that allows the pump to deliver the desired flow rate.

The output pressure of the pump is set using a back pressure regulator. Once the pressure is set, the flow rate to the process is established. The back pressure regulator (BPR) will isolate any changes that occur in the downstream system by making adjustments in order to keep its inlet pressure (the pump’s output pressure) at the target setpoint.

Accurate Flow Control with Equilibar Flow Control Regulators

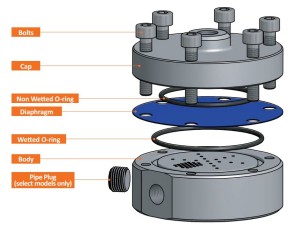

The unique technology in the Equilibar BPR is particularly applicable in this flow control scheme. This technology offers many advantages over traditional rising stem globe or needle control valves. The Equilibar uses a flexible diaphragm membrane as the only moving part. This design eliminates friction to allow the Equilibar flow control valve to respond precisely and with very low hysteresis. The Equilibar is a pilot operated design where the controlled flow rate is set by applying a setpoint pressure of compressed gas to the top side of the diaphragm. The advantages of the Equilibar are:

- The unique design of Equilibar flow control valve allows control of turn down ratios as high as 200 : 1, control of very small microflows, and also works well with mixed gas and liquid phases.

- Can control the flow of a pump with extremely high resolution. The frictionless diaphragm is the only moving part in the Equilibar and responds quickly to subtle changes in either the system flow rate or the pilot set point pressure

- The Equilibar is available in a variety of body materials and diaphragm types to meet the harshest of conditions.

- The simple construction is easy and low cost to maintain in the field.

Video Shows a How a Back Pressure Regulator Can Control the Flow of a Pump

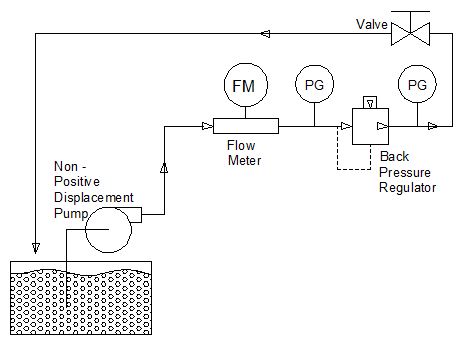

Click on the video link to see an Equilibar back pressure regulator used to control the flow of a pump in Equilibar’s engineering laboratory. The pump is a rotating impeller centrifugal type used to supply cooling water. In this video we demonstrate that the flow rate from the pump is repeatable, allowing you to come back to the same flow rate time and time again. A schematic of the laboratory setup is shown at right.

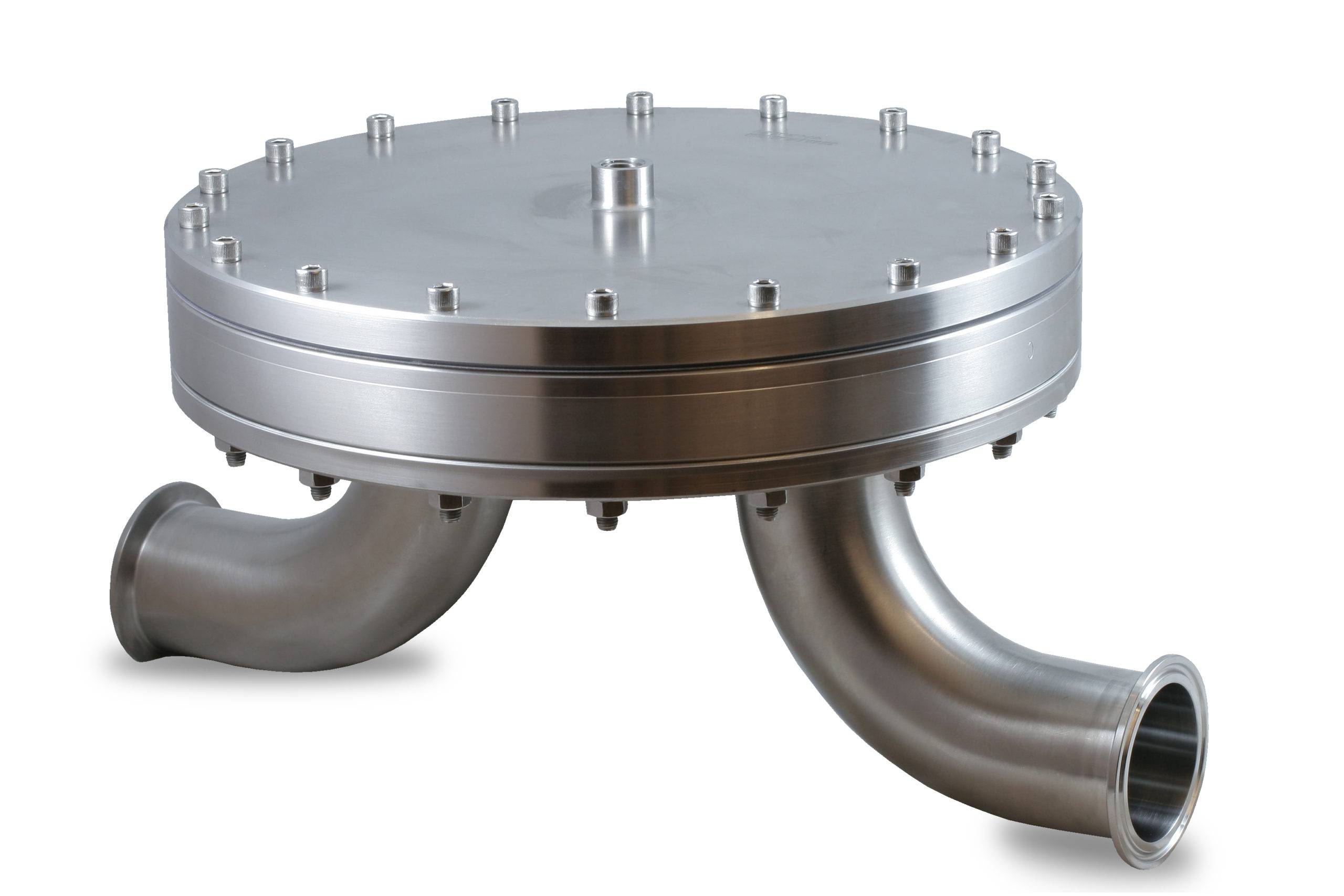

An exploded view of an Equilibar Multi-Orifice flow control valve. This unique design allows instantaneous frictionless control. The dome pilot pressure is controlled electronically (not shown).

Schematic of Equilibar Back Pressure Regulator in a pump discharge line to control the flow of a pump as demonstrated in the video. In the demonstration the water is fed back to the storage tank to reduce waste, but it is not used as a bypass line. The manual valve in the recirculation line is simulating process system demand situations.

One of our BD series regulators my be a good fit for your pump flow control application.

BD16 Industrial Back Pressure Regulator

- Port Sizes:

- 2"

- Typical Pressure Ranges:

- 0 - 1 in WC

- 0 - 28 in WC

- 0 - 5 psi

- 0 - 10 psi

- 0 - 20 psi

- 0 - 30 psi

- 0 - 60 psi

- Key Applications:

- Extrusion Pressure Control

- Tank Blanketing

- Fuel Cell Testing

- Water Treatment