CO2 Electrolyzer Technology

In CO2 electrolysis, research is ongoing to find efficient electrolyser technology to use at large scale. Solid oxide electrolysis cells (SOECs), molten carbonate electrolysis cells (MCECs), and gas diffusion electrodes (GDE) are all being studied. Electrolyzers assisted by catalysts, creating a multilayer electrolyzer stack is also under investigation. CO2 electrolyser technology is emerging as an important contributor to carbon reduction by using CO2 and H2O to create synthetic fuels.

Features of Equilibar valves making them ideal for CO2 electrolysis

- Wide Cv Turndown – Equilibar valves have a turndown ratio of 10,000:1 or greater, exceeding the range of traditional valves. The unique multi-orifice design of Equilibar BPR allows for stable pressure control across a wide Cv range.

- Controls mixed phase fluids – Equilibar’s multi-orifice design also enables precise control of mixed liquid/gas flow.

- Handles low or high dP across the valve – Equilibar BPRs, when sized properly for the required Cv, can maintain stable pressure control with either minimal pressure drop across the BPR, or with a large pressure drop, depending on the case. In large pressure drop situations, Equilibar valves avoid cavitation.

- Materials for aggressive conditions – The simplicity of the Equilibar design also allows easy tailoring of materials for the challenges of aggressive fluids.

- Instantaneous adjustments for maintaining pressure – The dome-loaded design and flexible diaphragm of the Equilibar BPR reacts nearly instantaneously to changes in process flow and adjusts its Cv accordingly to maintain the desired pressure.

Equilibar LF back pressure regulator for low flow electrolysis pressure control

Equilibar back pressure regulators used in “artificial photosynthesis” to make power from renewable sources

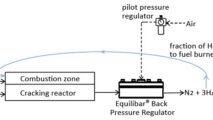

Our partners at Pressure Control Solutions (PCS) in the Netherlands worked with Evonik and Siemens on a project where the two companies combined CO2 electrolysis and gas fermentation in an “artificial photosynthesis” process they call The Rheticus Project. The project links the companies’ innovations in fermentation and electrolysis to make power from renewable energies.

PCS was called upon to find a solution for this project where a range of precision pressure setpoints was required. The customer found the Equilibar BPR technology to be “superior to conventional valve technologies”. Additionally, with the solution PCS designed, the customer was able to avoid crystallization issues related to salt in the electrolysis process. Read more in the case study on PCS website.

What are the products from water and CO2 electrolysis used for?

Energy researchers are optimizing water electrolysis for producing hydrogen as an energy source from renewable resources. Wind turbines and PV cells can be used as electricity sources for the electrolyzer to produce hydrogen for hydrogen fuel cells. The goal is to increase the use of renewable energy and decrease carbon emissions.

Oxygen gas produced in the reaction may be used for a variety of applications, including breathable O2 for space travel and submarines.

Carbon Monoxide is used in a pure form as a source for many industrial and fine chemicals or together with H2 in synthetic gas. When CO2 and H2O are reduced in a co-electrolysis process, syngas is produced and used to make fuels. It’s a win-win process taking CO2 from the atmosphere and using it to make renewable fuel.

About Equilibar back pressure regulators

The Equilibar® back pressure regulator is dome-loaded and, with its novel multiple orifice design, delivers instantaneous reliable control in the most challenging applications. The dome-loaded design means it requires a fluid (typically air or nitrogen) pressure applied to the dome of the BPR matching the desired inlet pressure. This setpoint pressure can be manually or electronically controlled. Learn how Equilibar back pressure valves work.

Request a QuoteContact an application engineer to discuss your application in more detail.