Advanced Temperature Control using Two-Phase Refrigerant Pressure Control

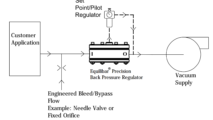

A novel method to make fast and precise temperature changes to the evaporator surfaces is by using an electronically actuated BPR downstream.

A novel method to make fast and precise temperature changes to the evaporator surfaces is by using an electronically actuated BPR downstream.

Equilibar® vacuum regulators don’t use springs, but instead utilize a 1:1 setpoint pilot pressure on their dome to provide improved precision.

For these applications, a vacuum regulating valve is needed on the processes requiring a lower vacuum pressure than the vacuum supply header.

Equilibar Vacuum Regulators are especially well suited for the complex demands of glovebox pressure control and can control down to the range of 1 inH2O (2 mbar)

The control of reactor pressure is critical and can be difficult due to aggressive chemicals, high temperature and pressure and mixed phase reactants.

In most vacuum holding applications, flow rate and pressure vary significantly at startup and during process disruptions. The EVR can help maintain control.

In filling a container, the blanketing gas in the head space must be vented to a disposal process to meet air quality and safety codes.

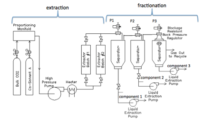

Back pressure control is a key part of supercritical CO2 extraction. The extraction vessel must be held at a constant pressure as part of a steady state circulation loop.

Using a direct acting vacuum regulator, such as Equilibar EVR series vacuum regulators, will control vacuum by limiting the flow .

The Equilibar Sanitary Back Pressure Regulator offers advantages over traditional control valves, including high turndown ratio and precision control for low flow rates

Dosing and blending systems must often be able to control over a wide range of flow rate to hold the desired conditions in the downstream process.

Our dome-loaded sanitary back pressure regulator can accurately control the differential pressure across a membrane in a wide range of flow rates.

The FD Series is designed to help meet Biopharmaceutical Water for Injection (WFI) Distribution Loop design principles.

Traditional flow control valves have difficulty in injection and metering applications where the downstream pressure is widely varying.

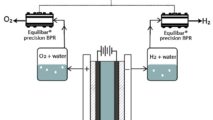

Equilibar® has a family of back pressure regulators to control the electrolysis process at a range of pressures, high or low, with extreme precision.

Equilibar offers a flow control valve that can dose at low and medium flow rates while also accommodating very high CIP flow rates

The new Blockage Resistant back pressure regulator from Equilibar uses a patent pending technology to resist the build up of ice in its internal passages.

For challenging filling applications, one solution is to install a high speed back pressure regulator near the exit of the nozzle manifold,

When Equilibar’s vacuum regulator is paired with the remote sense RSV pilot regulator, the precision performance is carried into higher flow rates.

The RSV is a highly sensitive mechanical vacuum pilot regulator designed specifically to provide closed-loop control of an Equilibar vacuum regulator (EVR).

The Equilibar® back pressure regulator with its multi-orifice design delivers superior precision and can accurately control the differential pressure across a membrane.

Geoscientists use high pressure core testing to determine permeability & porosity of reservoir rock to ensure that gas production is efficient and safe.

Equilibar FD Series sanitary back pressure regulator can be used as a flow control valve to control flow at user points along WFI loop.

The Equilibar® back pressure valve can be used as a level control valve to control steady state liquid flow through a range of flow coefficients.

Our vacuum regulator offers exceptionally fast response that automatically compensates for fluctuations in flow rate without complex control loops.

Our back pressure regulator paired with our electronic pilot controller provides a simple, elegant level control option that is easy to install and maintain.

An Equilibar back pressure regulator (BPR) has several advantages over other BPRs in flow chemistry applications.

Our back pressure regulator paired with our electronic pilot controller provides a simple, elegant level control option that is easy to install and maintain.

Our dome-loaded sanitary back pressure regulator can accurately control the differential pressure across a membrane in a wide range of flow rates.

Equilibar FD Series sanitary back pressure regulator can be used as a flow control valve to control buffer blending for gradient chromatography.

An FD Series back pressure regulator is capable of controlling pressure at extremely low flow rates, allowing a more exact mixture of ingredients during product blending.

How to use an Equilibar® back pressure valve in polymer chemistry process control