Flow Control Schemes using Equilibar Dome Loaded Valves

Equilibar BPRs have ultra high resolution, zero hysteresis, and zero dead-band. This can be useful for alternative flow control.

Equilibar BPRs have ultra high resolution, zero hysteresis, and zero dead-band. This can be useful for alternative flow control.

The Equilibar BPR can be used to obtain a stable process pressure through a wide range of flow rates for gas flow meters.

Equilibar® precision back pressure regulators are being used successfully in research reactor applications using supercritical fluids.

The petroleum industry has special requirements for back pressure regulators for conducting core analysis of rock samples.

Altitude test chambers are used by many different industries to simulate the conditions of varying atmospheric pressure.

Dental vacuum systems typically use pumps that may benefit from the improved vacuum control provided by Equilibar’s vacuum valves.

Many applications require control of pressure in the absolute range. Equilibar offers good solutions for these situations.

Some applications require pressure control that crosses from negative to positive pressure relative to the atmospheric pressure.

Pressure bypass valves control pressure by diverting a portion of the flow, typically bypassing fluid from the outlet of a pump.

Many polymer extrusions are made by the use of vacuum sizing boxes. The Equilibar Vacuum Regulator can improve product quality.

The Equilibar precision back pressure can be used as an alternative to traditional flow control valves in certain applications requiring very high resolution and zero deadband.

The Equilibar BPR controls pressure with a multiple orifice design, with more orifices engaging as flow rate increases.

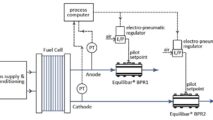

Fuel cell testing systems benefit from Equilibar products’ high sensitivity in the low to mid pressure ranges.

An Equilibar® low pressure control system can be used to precisely control the pressure of the air inside the extrudate.

Equilibar vacuum regulators offer improved cycle time in the packaging process, consistent gas fills and fewer puffy packages.

The installation of an Equilibar vacuum regulator can be the solution to the many challenges of a centralized vacuum system.

Many vacuum regulators simply do not offer the accuracy required to selectively distill fluids with close boiling points. Equilibar EVRs excel.

Many small molecule separations require transmembrane pressures in the range of 1 psi. Equilibar BPRs can meet the challenge.

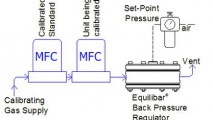

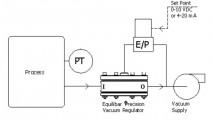

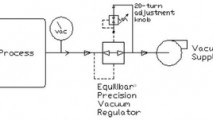

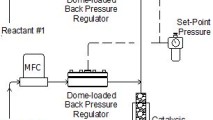

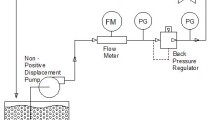

These schematics show some of the applications that can be used to accomplish computer automation of flow rate.

A properly sized pressure sustaining valve can create just the necessary amount of resistance to accurately control pump discharge pressure.

Reduce pulsation in circulating liquid systems, such as those used with positive displacement pumps.

Maintain stable output flow rate downstream of positive displacement pumps such as gear pumps, lobe pumps and diaphragm pumps.

Back pressure control valves can be used to ensure that vessel pressure does not exceed the rating of rupture discs.

The Equilibar vacuum regulator uses an unusually large diaphragm area to facilitate lightning-fast response to changes in vacuum pressure.

While MFCs are a great solution for laboratory flow control and have accuracy as high as 0.5% of reading, they have limitations that Equilibar can address.

In fuel system component testing, it is best to get close to actual operating conditions, which means varying the back pressure.

The Equilibar® precision back pressure regulator is designed and demonstrated to excel within the demanding requirements of catalysis research.

The Equilibar blockage resistant regulator uses a patent pending technology to resist the build up of ice during supercritical CO2 extraction.

A benefit of using a back pressure regulator to control the flow of a pump is that it is easily manufactured from materials compatible with process fluids.

The key to the ultra wide range of flow comes from the high resolution of the Equilibar BPR coupled with the Equilibar QPV.

One common method to minimize or prevent bubble evolution is to increase the pressure at the outlet of the Coriolis meter.

For demanding dosing applications, a back pressure regulator can isolate the control valve from downstream pressure variations.