Clean-In-Place Velocity Requirements

Standard CIP requirements are to achieve 5 ft/sec of fluid velocity during the cleaning process to assure good flushing and rinsing. If 2” (DN50) tubing is used, for example, then a CIP cleaning and rinsing flow rate of nearly 45 GPM is required. Sanitary processes are typically designed such that several serial components are cleaned at a time. For example, a pump, filter, transfer line and several valves might all be part of a cleaning loop.

Sizing for Dosing and blending applications

For many dosing, blending and injection processes, the pumps and valves are sized to achieve precise blending parameters sometimes less than 1 GPM. This equipment is oftentimes too small to achieve the required CIP flow for proper cleaning. Typical dosing valves have good control within a 20:1 or 30:1 flow rate range, making it difficult for process engineers to specify such components for both minimum dosing flow rates and maximum CIP flow rates.

CIP Bypass Valves

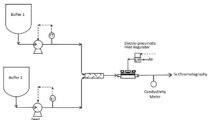

One typical solution is to install a CIP bypass line around the dosing valve. In the example below, a pressure control valve (PCV) is used as a dosing valve. During the CIP process, the CIP bypass line opens up to allow proper flow of CIP fluids. In other applications, diaphragm block valves are used to open up and engage a pressure relief valve or back pressure regulator. Each of these solutions adds additional complexity and testing requirements to the process design. In some cases this solution may leave small sections of the tubing without the benefit of the cleaning under the required flushing velocities.

Alternative Solution: Valve with Very Wide Flow Rate Range

The Equilibar sanitary back pressure regulator (BPR) functions in a unique way compared to other sanitary valves. Instead of using a globe-style valve seat with limited flow range, it uses a direct sealing diaphragm and 1:1 dome air loading to modulate the pressure and flow. The interaction of the flexible diaphragm and the dozens of parallel orifices allows for a very high Cv turn-down ratio. This exceptionally broad flow range allows the process engineer to specify a single valve capable of precise control during dosing and blending, while also opening up during the Clean-In-Place process to facilitate robust process flushing.

Learn more about how the Equilibar dosing control valve works.

Contact an Equilibar engineer to discuss your flow control application in more detail.

Sanitary back pressure regulator

Control Valve with Wide Flow Rate Range