B6R Blockage Resistant Back Pressure Regulator

| Port Sizes: |

|

||||

| Max Pressure (Std Body Mat’l) |

|

||||

| Body Material (Standard): |

|

||||

| Max CV: |

|

||||

| Key Applications: |

B6R Blockage Resistant Back Pressure Regulator

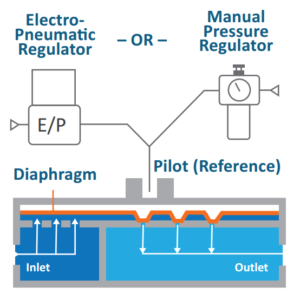

The Equilibar® B6R and BR models are variants of the popular Equilibar back pressure regulators. This series integrates technology to optimize for supercritical applications. These features maintain high precision control while reducing the Joule-Thomson effect of supercritical process fluids passing through the outlet orifices.

The key design feature of this regulator series is a downstream expansion cavity that provides a continuously increasing cross sectional area to eliminate convergence points for ice build-up during decompression.

The body is machined from premium stainless steel 316/316L dual cert alloy bar stock. The shape of the internal passages prevents the accumulation of ice or viscous oils so that the B6R remains free to keep the pressure regulated at the target setpoint.

The flexible diaphragm membrane is the only moving part. This membrane directly seals against field of multiple parallel orifices for instantaneous and precise pressure control. Diaphragms can be ordered in polyimide, PTFE, or PEEK depending on the co-solvents used and the maximum process temperatures.

Specially designed O-ring grooves reduce stress during rapid decompression which increases O-ring life. O-ring choices include Buna-N, Viton, PTFE, and DuPont Kalrez as determined by your application.

The BR back pressure regulator series has several fitting options including tube stub, NPT and an outlet flange.

Contact an Equilibar application engineer to discuss your specific needs.

B6R Blockage Resistant Back Pressure Regulator

Pressure Control Valve for Supercritical Fluid Extraction Supercritical CO2 Pressure Regulator Resists Blockage How Equilibar Back Pressure Regulator Works

B6R Blockage Resistant Back Pressure Regulator

B6R Blockage Resistant Back Pressure Regulator

B6R Blockage Resistant Back Pressure Regulator

Weight:

3.8 lbs (1.72 kg)

Dimensions:

Fitting/Threads:

Standard: 1/4″ or 3/8″ NPT

Optional: Custom Flanged Outlet; Tube Stub

B6R Blockage Resistant Back Pressure Regulator