An herbal extractor in Arizona has successfully used the Equilibar Blockage Resistant back pressure regulator to accurately and reliably control the extraction of organic compounds.

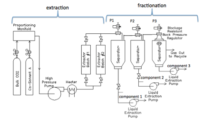

Technicians designed and developed a steady state extraction process to circulate high liquid throughput of 7 to 14 liters/minute CO2, controlling extraction pressures ranging from 1750 psi to 5000 psi. The back pressure regulator has been performing trouble-free for two years, with over 1200 hours logged on a single proprietary polymeric diaphragm.

Back pressure control is a key part of supercritical CO2 extraction because the extraction vessel loaded with plant matter must be held at a constant pressure as part of a steady state circulation loop. The dissolved mixture of oils and organics must be let down through a control valve to initiate separation. The expansion of CO2 creates severe cooling of the mixture due to the Joule-Thompson cooling effect. Ice and viscous oils present blockage challenges for traditional control valves, which often require special heating methods.

The Equilibar BR Series is designed specifically to handle the severe service conditions of supercritical CO2 letdown. The BR design includes several features to prevent icing and blockage, and can often be used at high flow rates without disruption.

In the Arizona installation, the BR is configured with an open bottom outlet and installed to eject the ice and viscous organic oils directly into a heated separation vessel. Unlike other valves, the BR’s design allows it to function without any external heating elements when configured in this manner.

This Arizona operation learned to optimize both their extraction rate and the ratio of desired organic compounds by controlling both the temperature and pressure in the extraction vessel. Like all Equilibar back pressure regulators, the BR uses a 1:1 fluid pressure applied to its dome to control its inlet pressure. The multi-orifice design operates with very high precision across wide flow rates, allowing for easy control of extraction conditions.

Many plant extractors are keenly interested in separating the organic compounds to study and optimize their medical benefits. Other extraction clients control the let-down in two stages across two serial separation vessels. By using two Equilibar BR regulators to precisely these two vessels, technicians are able to actually accomplish compound separation in the same process as extraction.

Learn more about Equilibar BR back pressure regulators in supercritical extraction processes.

Plant matter extractor in Arizona uses Blockage Resistant back pressure regulator to maintain extraction pressure. The outflow of the BPR contains ice and extraction oils, and discharge directly into the separator vessel to avoid blockage issues. No heat jackets are used on the BPR.

One of our BR series regulators could be a good fit for your plant matter extraction application.

B6R Blockage Resistant Back Pressure Regulator

- Port Sizes:

- 1/4"

- 3/8"

- Typical Pressure Ranges:

- 0 - 2000 psi

- 0 - 2500 psi

- 0 - 3000 psi

- 0 - 4000 psi

- 0 - 5000 psi

- 0 - 6000 psi

- Key Applications: