The Challenge

Food packaging of fresh meats and vegetables is often performed today using Modified Atmosphere Packaging (MAP) in which air is rapidly removed and an inert gas is substituted. To do this economically, the gas exchange processes must occur quickly, challenging the performance of traditional gas handling components and systems. Under rapidly varying flow rates, traditional vacuum control may not be able to keep up with the demand, in which case the injection of inert gases must be delayed to compensate for the uncertain application of vacuum. Not only does this slow down the process, it also imparts variability into the overall gas composition in the product.

To avoid process problems, it is important that the vacuum be consistent from package to package and not deviate from the setpoint.

The Solution

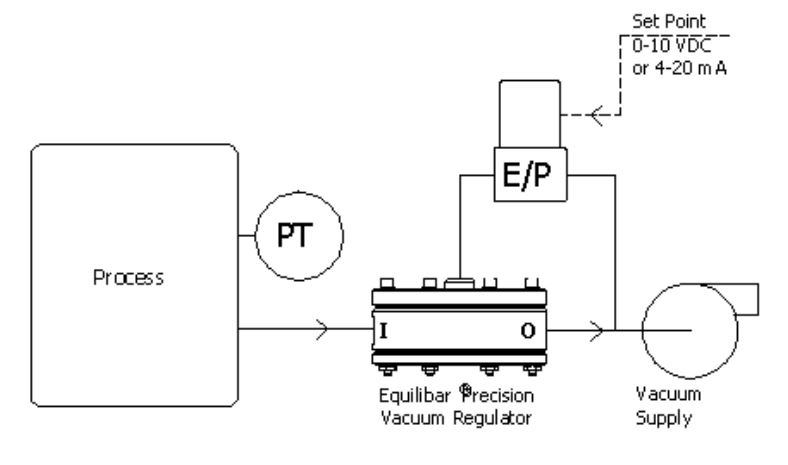

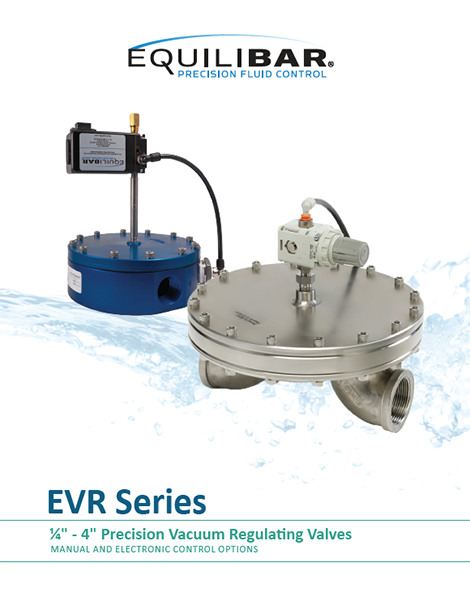

The Equilibar EVR Series of precision vacuum regulator is a good fit for the demands of this application. By providing stable vacuum pressures under rapidly varying flow rates, the Equilibar vacuum regulator (EVR) dramatically reduces the atmospheric variability from package to package, thereby improving the quality of the product and the productivity of the process.

The EVR’s unique technology controls vacuum pressure independent of the vacuum supply pressure source. This allows multiple vacuum levels to be adjusted independently of the others all while being supplied by a common house vacuum supply system. The EVR is able to provide high flow rates and is available from 1/4 inch through 4 inch port size. The lightweight flexible diaphragm is the only moving part, which allows the EVR to respond to changes in flow rate in milliseconds. Additionally, the near frictionless motion of the diaphragm allows vacuum pressure to be controlled very precisely. With lightweight PVC plastic bodies available to fit most applications, the exact same design is also available in stainless steel 316L to handle high temperature vacuum or chemical washdown environments.

The Results

Customers report improved cycle time in the packaging process, consistent gas fills and fewer puffy packages. See the complete whitepaper for more details.

Learn more about Equilibar’s vacuum regulators