What is the purpose of a pulsation dampener?

A pulsation dampener is used to improve process effectiveness by reducing pulsating flows caused by positive displacement pumps. Dampeners reduce pulsations to ensure a smooth fluid flow so that processes downstream of the pump are accurate, efficient and safe. Pulsation dampening is particularly important in biopharmaceutical processing due to the sensitivity of the cells (upstream), and biomolecules (downstream) to changing process conditions. Single use systems (SUS) benefit from using pulsation dampeners during media transfer, perfusion, filtration, chromatography and other processes.

What are the challenges caused by pulsations in bioprocessing?

In bioprocessing, pulsations caused by positive displacement pumps (peristaltic, diaphragm, and others) can create upstream and downstream processing challenges including:

- Difficulty in measuring flow accurately, affecting process control

- Stress on delicate cells or biomolecules

- Decreased filtration effectiveness due to variability in TMP

- Disturbances in chromatography resin

- Possible Inaccuracies in filling

All of these situations cost time and money or affect product yield / quality, so keeping them to a minimum is important.

Equilibar patented active pulsation dampener for single use bioprocessing

How to control pulsations in single use bioprocessing

Process pulsations can be reduced by adding a pulsation dampening device downstream of the pump. Equilibar engineers have leveraged their fluid control knowledge to design a pulsation dampener for single use bioprocessing systems.

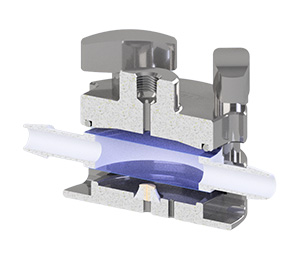

This unique, non-restrictive device reduces system flow and pressure pulsations using a Class VI polymer single-use hollow body between two integrated diaphragms that face process pressure. The polymer body is enclosed in a permanent stainless steel housing with wing nut closure for easy change-outs.

The Equilibar® single use pulsation dampener uses pneumatics and self-adjusts its setpoint to match system pressure real-time to dampen pulsations. This behavior is similar to how the Equilibar SDO back pressure valve dampens pulsations, but is optimized for this dedicated dampening device.

The non-wetted sides of the diaphragms are pressurized using a pressure regulator connected to a port on the top and bottom of the stainless steel housing. This patented system will adjust its internal pressure in response to the force and direction of each pump pulsation against the diaphragms, reducing pulsation amplitude. Early trials have shown >70% reduction on amplitude, and establishes a more uniform pressure profile.

What is different about the Equilibar pulsation dampener?

This dampening device, when compared to other single use dampeners, actively responds to pulsations which improves dampening capabilities compared with passive dampening devices. Furthermore, it’s compact size significantly reduces footprint, which makes it much easier to integrate. The Equilibar pulsation dampener has optimal performance in any orientation.

CONTACT US for more information or to discuss a trial.

Watch how an Equilibar single-use pulsation dampener can reduce pump-induced pulsations by 10x!

Applications where using an Equilibar single use pulsation dampener can be beneficial:

General applications

- Downstream of any single use positive displacement pump

- Upstream of single use flow meters – some flow meters experience a deterioration in accuracy when flow is unstable. A dampener upstream helps manage pressure disturbances to maintain accuracy.

Upstream bioprocessing applications

- Perfusion: Tangential flow filtration (TFF) transmembrane pressure (TMP) control on retentate and permeate* lines

Downstream bioprocessing applications

- Buffer dilution: Buffer positive displacement feed pump outlet

- Clarification, Ultrafiltration/Diafiltration: on TFF retentate and permeate* lines

- Upstream of depth filters

- Upstream of chromatography column

- Gradient elution systems : flow meter stabilization on pump VFD feedback loop for buffer mixing

- Filling lines: downstream of feed pump

*Use on Permeate line only if vessel pressure is dynamic. No need if pressure is static.

Looking for a stainless steel sanitary pulsation dampener?

Contact Us Today