Cavitation is a damaging phenomenon that engineers need to avoid in both pumps and control valves. Damage occurs in the throat of the valve when local static pressure drops below the vapor pressure of the fluid, causing the formation and subsequent collapse of high-energy microscopic bubbles. The collapse of these bubbles can cause severe pitting and can also create undesirable noise.

Equilibar valves have a unique throat geometry with multiple parallel flow paths that has been shown to avoid cavitation issues (both pitting and noise).

If your flow control or back pressure control application is experiencing cavitation issues, contact one of our engineers to see if our products might be a good fit for your application.

Closer Look at Causes of Cavitation

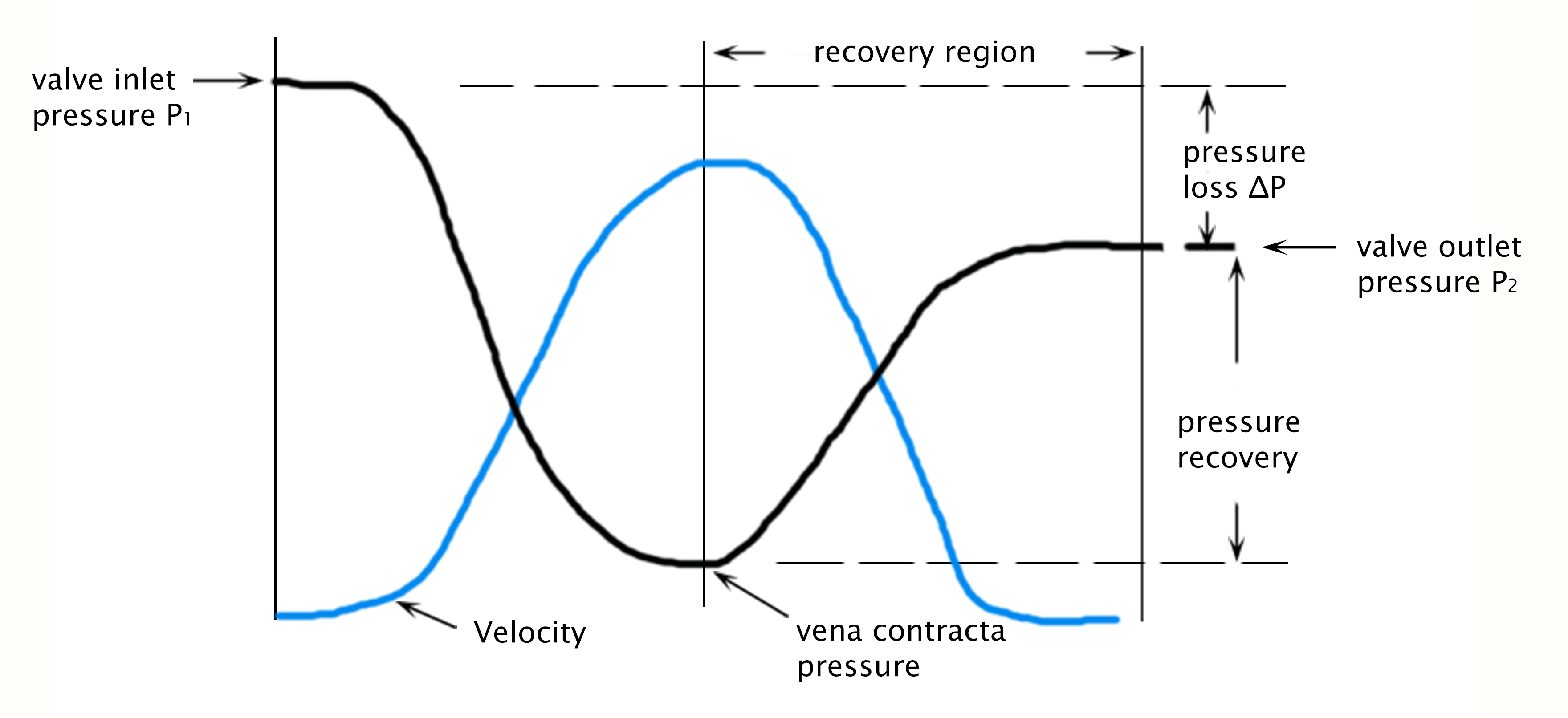

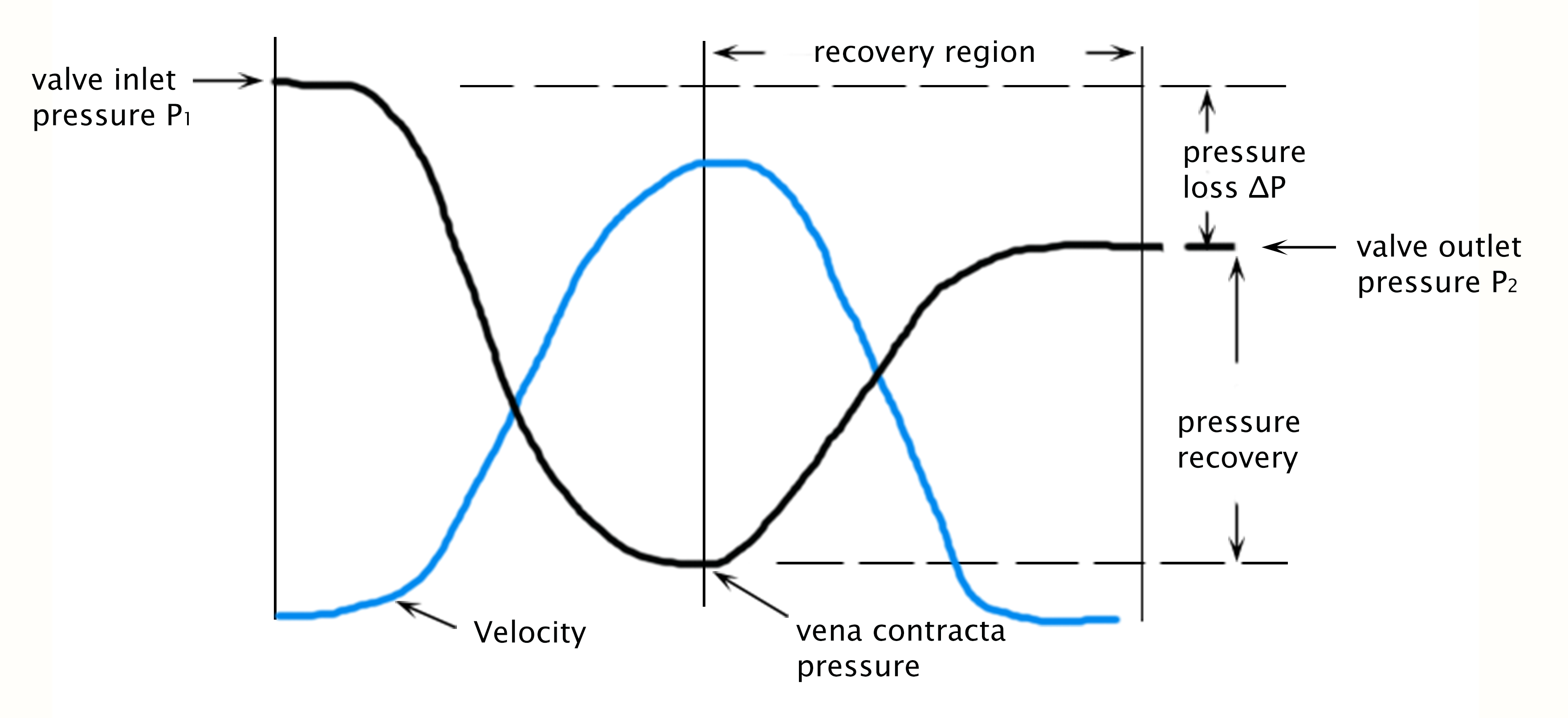

All control valves work by creating a pressure drop in the valve seat. Typically, fluid flow is accelerated to a maximum velocity in the throat of the valve seat (the vena contracta) where the cross sectional area is smallest. As the fluid decelerates downstream of the throat vena contracta, a portion of that kinetic energy is converted back to potential energy (pressure), causing a partial pressure recovery.

Chart showing reduction in static pressure as velocity is maximized in the valve vena contracta. Image courtesy Jordan Valve.

This pressure recovery is problematic because it provides for the fluid to be briefly at a pressure lower than the valve outlet. For many applications where the valve outlet is near the vapor pressure of the fluid, microscopic cavitation bubbles can occur at the vena contracta, then collapse along with the recovered pressure.

The collapsing of these microscopic bubbles directs damaging energy onto the surface of the valve, causing pitting that can lead to failures. (Fun fact: this Phys.org article claims that a collapsing cavitation bubble reaches a temperature 4 times hotter than the sun!)

Different valve designs have different pressure recovery factors, although all standard valve `designs (gate, butterfly, ball) are considered subject to cavitation problems.

Traditional Solutions to Address Valve Cavitation

The valve industry has developed several effective means to avoid the damaging effects of cavitation in common applications such as boiler feedwater and other high pressure water systems. These methods include:

- The use of multiple valves in series–installing a valve or BPR downstream of a control valve protects the upstream valve.

- The use of hardened trims such as Stellite–this approach is commonly used in steam, but is not suitable for chemically corrosive fluid.

- Special trims are available to reduce noise and eliminate cavitation damage.

- Radial Flow trims

- Caged Orifice trims

- Axial Flow Path trims

Many of these designs are mechanically more complex, and these designs are more commonly seen in larger, higher-energy dissipation applications such as municipal water and utility systems. A few models are available in stainless steel body and trim.

Equilibar as Anti-Cavitation Valve Alternative

Like traditional devices, Equilibar control valves also create a pressure drop by accelerating the fluid to a type of throat near the point where the diaphragm and orifice meet. Unlike traditional valves, however, Equilibar’s direct-sealing diaphragm multiple orifice design features a significantly different geometry of fluid acceleration and deceleration.

Over the past 15 years, Equilibar engineers have specified our BPRs for several thousand different liquid applications. An analysis of customer feedback and returns over this time strongly suggests that our valves are not subject to damage or noise in these applications.

To confirm this hypothesis, we intentionally subjected our 1” GSD8 valve to a warm water recirculation application around up to 90 psig that is considered a classic cavitation application. After 40 hours, absolutely no signs of pitting or damage were observed.

Advantages of Equilibar Valves in Cavitating Applications

While the anti-cavitation solutions outlined above are highly suitable for utility applications and larger, high energy dissipating applications, they may not be suitable for highly demanding chemical or research applications that:

- Require materials suitable for highly corrosive applications

- Require very wide flow rate ranges (100:1 or higher turndown ratio)

- Require simpler or more compact designs

- Require sanitary features for food or biopharma applications

Product Details

Equilibar flow control valves

Equilibar back pressure regulators

Contact Us

Equilibar engineers are constantly looking for new ways to address demanding customer challenges. If you require a zero cavitation valve and the traditional valve solutions are not a good fit, contact our engineers to discuss whether your cavitating application might qualify for a free trial.