Vacuum drying of API – or Active Pharmaceutical Ingredients – is just one of several steps in the manufacturing process of these therapeutic medicines. API are synthesized and purified using a combination of chemical reactions and physical processes depending on the complexity of the API. The drying process near the end removes excess water using various methods such as oven drying, spray drying and vacuum drying, sometimes in a multi-step process.

Benefits to using vacuum conditions for API drying include:

- Lower pressure allows efficient drying at lower temperatures, which benefits products that cannot withstand high temperatures.

- Vacuum can help remove entrapped liquid and obtain low final moisture content.

- Vacuum serves to remove solvent from the system.

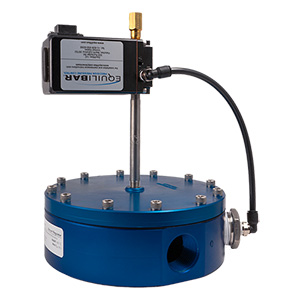

Process automation, precision vacuum control and the ability to handle chemicals are important design factors in API vacuum drying. An Equilibar vacuum regulator (EVR) is an excellent solution for this application.

Example: Using an Equilibar EVR in API Processing

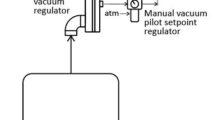

In spray-drying techniques, the API is combined with a volatile solvent to assist in the drying process. To remove the solvent and complete the drying process, the API is sent to a vacuum drying vessel, oftentimes under a nitrogen blanket, with an agitator and heating system. Consistent vacuum must be maintained for efficient drying and removal of volatile solvent gases for recovery. A simplified schematic is shown below.

The Equilibar vacuum regulator, when combined with an electronic pilot setpoint controller, maintains precise and consistent vacuum control despite changes in flow or moisture conditions during drying. An Equilibar vacuum regulator can also be manufactured with chemical resistant materials to accommodate solvents. Read about chemical vacuum processing with Equilibar vacuum valves in our article in Processing Magazine.

Contact an Equilibar application engineer for more information.