Precisely controlling vacuum pressure is critical in many processes because the mixture being distilled may contain several liquids with close boiling points. Accurately controlling the vacuum allows for much higher selectivity in the distillation process.

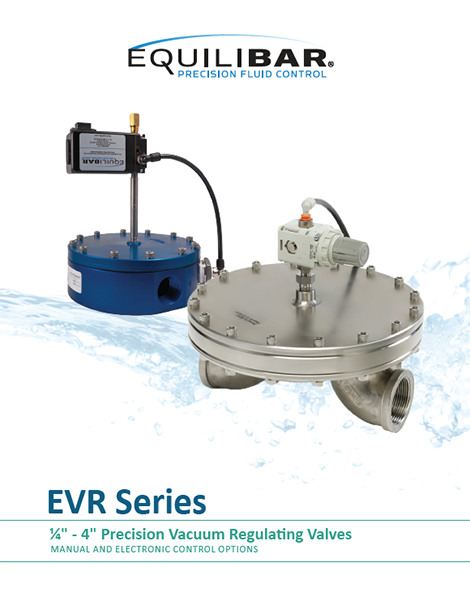

Many vacuum regulators simply do not offer the accuracy required to selectively distill fluids with close boiling points. Moreover, regulators that are sensitive enough are often so fragile that they cannot stand up to the corrosive chemistries or elevated temperatures usually encountered in vacuum distilleries. The Equilibar EVR Series of precision vacuum regulator is able to solve both the accuracy and durability problems in one complete package.

Accurate Control for Precision Distillation

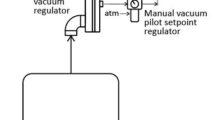

The Equilibar EVR controls vacuum pressure accurately. It is able to hold the vacuum precisely at the required set point regardless of fluctuations in the system flow rate or variations in the supply vacuum pressure. The EVR can achieve this because it uses innovative direct diaphragm sealing technology. A responsive flexible diaphragm is the only internal moving part. The diaphragm is nearly frictionless in its movement and does not have accuracy-robbing hysteresis and “stiction” (static friction) like traditional ball, gate, or butterfly vacuum regulating valves have. The diaphragm has very low mass and will respond to changes in system flow rate within milliseconds.

Precision Control for High Vacuum Applications Involving Distillation

Some vacuum applications require precise control at high vacuum in the range of 100 microns Hg (abs) or 0.1 mbar (abs), which can be hard to control. In a closed-loop automated setup, Equilibar EVR vacuum regulators are able to successfully control high vacuum. This may be of particular use in vacuum distillation or other analytical vacuum processes. Below is a video demonstrating high vacuum automation.

Rugged Design Handles Extreme Temperatures and Chemistries

The EVR is body manufactured from bar stock SS316L for maximum durability and chemical compatibility. The flexible diaphragm material is carefully selected to match the application’s temperature and media. The rugged design of the EVR can control media with temperatures ranging up to 325 C. The availability of PTFE, Hastelloy, and Polyimide/Kapton diaphragm materials means that almost all media combinations can be regulated with the EVR.

Polymer Devolatilization

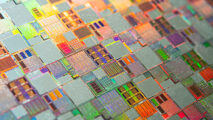

The removal of volatile substances from polymers, which is called devolatilization, is one of the most important operations in polymer manufacture, and it works like vacuum distillation. Strict environmental requirements demanding lower residual organic volatiles in plastic materials have led to a need for efficient devolatilization in polymer production.

In general, polymer devolatilization starts with the polymer flowing through a heat exchanger and then into a vacuum flash chamber where the volatile organic compounds (VOCs) are separated from the polymer. The devolatilization chamber is similar to a vacuum distillation column where the VOCs exit through the vacuum line at the top of the chamber and the polymer is discharged from the bottom section of the devolatilization chamber. An Equilibar vacuum regulator is a good solution in this application as well.

Learn more about Equilibar’s vacuum regulators