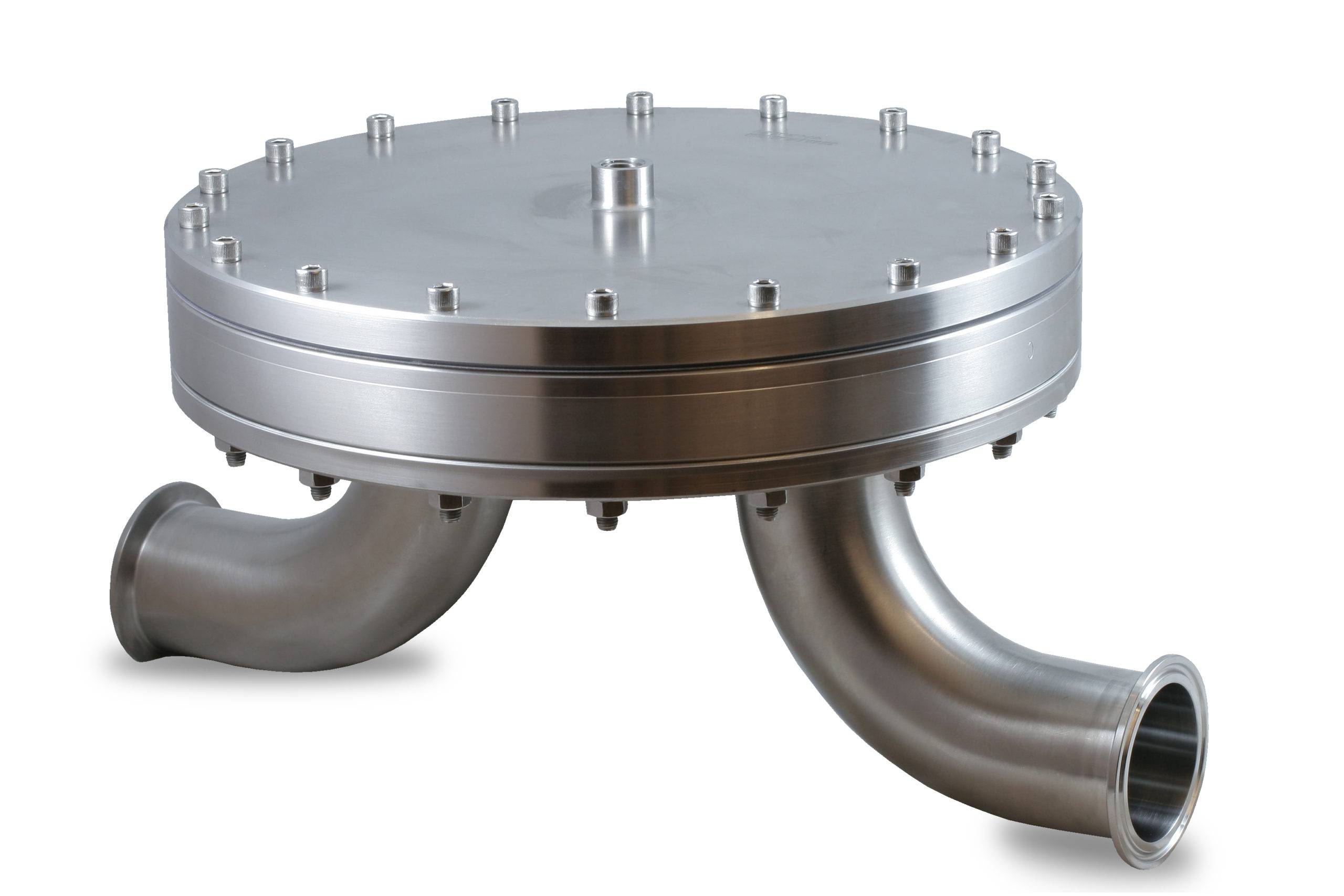

BDM16 Industrial Back Pressure Regulator

| Port Sizes: |

|

||||

| Max Pressure (Std Body Mat’l) |

|

||||

| Body Material (Standard): |

|

||||

| Max CV: |

|

||||

| Key Applications: |

|

BDM16 Industrial Back Pressure Regulator

The 2″ BDM16 back pressure regulator is useful for a wide variety of liquid and gas services through industry. It is available with female NPT ports (standard), and also with integral flanges or tri-clamp flanges. The BDM models are designed to be used at slightly higher pressure conditions than the BD models.

BD Series

BD Series Back Pressure Regulators are designed for use in industrial applications with high flow rates. Competitive valves are often cast from materials (such as carbon steel and cast iron) that do not handle aggressive chemicals and corrode after short periods of use. The BD Series is available in all SS316L and PTFE construction for the most demanding chemical applications.

The BD Series valves are extremely durable and built to last. With the diaphragm as the only moving part, maintenance of the BD regulator can be performed quickly on site for a very nominal expense, typically less than 10% of the cost of a new valve. Competitive valves have repair kits which cost up to half the price of a brand new valve and take hours to rebuild.

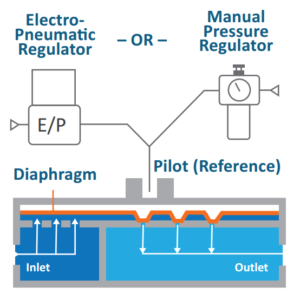

The BD Series is available in pipe sizes from 1.5″ to 4″ in pressure ranges up to 150 psig. They are true 1:1 dome loaded back pressure valves, meaning that 1 unit pilot pressure yields 1 unit upstream pressure. There are many advantages to using our dome loaded design, including extremely wide range of Cv with a single unit, frictionless operation with no cracking pressure, and no hysteresis as found in traditional spring loaded regulators.

Contact an application engineer for more information.

BDM16 Industrial Back Pressure Regulator

How Equilibar Back Pressure Regulator Works

BDM16 Industrial Back Pressure Regulator

BDM16 Industrial Back Pressure Regulator

- Extrusion Pressure Control

- Tank Blanketing

- Water Treatment

BDM16 Industrial Back Pressure Regulator

Weight:

Dimensions:

Stainless Steel (SS) Models

Stainless Steel (SS) Models

DIM A – 11 in (280 mm)

DIM B – 5.7 in (145 mm)

Fitting/Threads:

Standard: NPT

Optional: BSPP; 150# Flange; custom

BDM16 Industrial Back Pressure Regulator