During the process, the differential pressure across the TFF membrane (called Trans-membrane pressure or TMP) must be maintained within a narrow range to provide the highest flux, and to prevent membrane gelling (fouling caused by retained product deposition). The Equilibar® sanitary FDO or single use SDO back pressure regulator (BPR) allows you to do that. With its multi-orifice design, the FDO and SDO deliver superior precision and can accurately control TMP across a wide range of flow rates. The high turn-down makes the Equilibar BPR an excellent choice in traditional tangential flow filtration control.

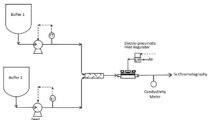

In the schematic above, Equilibar® SDO single use back pressure regulators (BPRs) are used in both the retentate and permeate lines of the TFF process. Setpoint signals are sent to the electro-pneumatic pilot regulators from the main control system to set the pilot pressures on the Equilibar BPRs. This setup maintains a stable target pressure differential across the filter membrane for effective TFF process results.

In systems where the permeate head space is vented through a sterile filter, or where pressure is known to be constant, the setup can be configured with a single SDO back pressure regulator controlling the retentate line.

In single use (SU) systems, the SDO offers a revolutionary upgrade in TMP control. Conventional SU systems typically use a tubing pinch valve, which by their nature are very difficult to set, and not easily adjusted to precision. By contrast, the SDO with its 1:1 relationship between pilot pressure and process pressure enables precise setpoints and ease of adjustment. “Set and Forget” is a common phrase we hear. The SDO can also be automated with an I/P and PID controller to precisely control TMP to follow the membrane manufacturer’s TMP/Flux curve, which will minimize fouling, and improve titer.

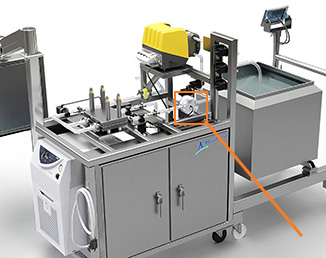

Agilitech single use TFF skid with an Equilibar SDO back pressure regulator

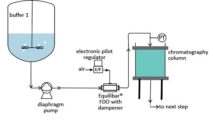

Equilibar FDO Sanitary back pressure regulator used in membrane pressure control applications

Single Pass Tangential Flow Filtration

In recent years, new emphasis has been placed on continuous drug manufacturing, as opposed to batch manufacturing, for improved yield and productivity. Single pass tangential flow filtration (SPTFF) is a relatively new innovation that provides for continuous separations while minimizing pump shear by eliminating unneeded and bulky pumps and tanks. One advantage of single pass TFF is reduced processing time.

Design constraints for single-pass TFF are more critical and typically require either multiple serial filter membranes or overall

lower feed fluxes or their combinations to achieve the desired residence time within the filters. Scientists at Sanofi found that unlike the traditional fixed TMP regime used in multi-pass TFF, SP-TFF requires real-time modulation of the transmembrane pressure (TMP) to achieve optimal control.

The Sanofi team used Equilibar® back pressure regulators to test a novel feedback control system which would maintain the retentate concentration at the desired target (grams/liter). The result was a stable six-day run that maintained on-target permeate flux with minimal fouling and efficient buffer utilization. The data shows that over the 6-day trial, the TMP was maintained to within 0.4psi, a control window that is not achievable with other traditional technology available today.

About the Equilibar SDO

The Equilibar single use pressure control valve was developed in response to the biopharma industry’s rapidly expanding requirements for low cost components that can be sterilized through radiation and disposed of after use. The Single Use valve is also an excellent solution for other applications that require single use components.

The valve’s patent pending design offers USP Class VI polymers that can be sterilized as an assembly. The Single Use Equilibar BPR features the same dome-loaded multiple orifice technology as all Equilibar products, delivering instantaneous control, frictionless operation, superior precision, and exceptionally wide flow rate ranges. Its strengths are particularly well suited to control the transmembrane pressure in tangential flow filtration control applications.

Learn more about our back pressure regulator technology and about other Equilibar products designed for use in sanitary process.

Contact one of our applications engineers to help select the perfect back pressure regulator for your filtration application.