Unparalleled Precision for Research and Industry

Equilibar fluid and pressure control products deliver reliable performance for some of the world’s most complex process conditions. Our dome-loaded, multiple-orifice technology works in a radically different way, providing solutions for difficult problems in a broad range of industries, including catalysis, oil and gas, fuel cells, and aerospace. We also have sanitary valves for biopharma processes.

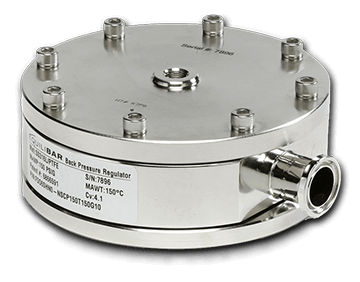

Research Back Pressure Regulators

Equilibar research back pressure regulators offer compactness, flexibility and instantaneous response for laboratory and reactor systems. More

Industrial Back Pressure Regulators

Equilibar industrial back pressure regulators are ideal for a wide range of use including sanitary processes, fuel cells, and oil and gas. More

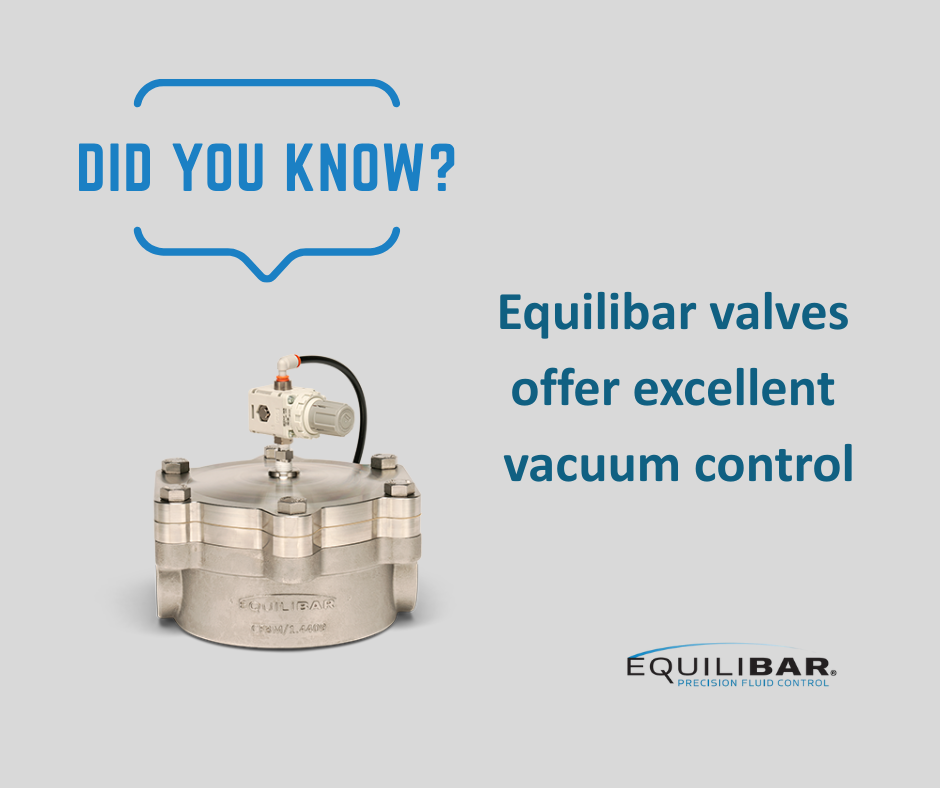

Vacuum Pressure Regulators

Equilibar’s vacuum regulating valves use a flexible diaphragm with multiple orifices to offer 5X the stability of traditional spring valves. More

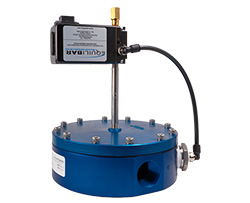

Electronic Pressure Regulators

Equilibar offers a wide range of precision electronic pressure control products for process automation and for providing pilot set-points. More